Environmental Performance Data

Reporting Period

Fiscal 2021

(January 1 to December 31, 2021)

Guidelines Used for

Reference

Ministry

of the Environment, Environmental Report Guidelines

(2012 Edition)

Ministry of the Environment,

Environmental Accounting Guidelines (2005

Edition)

Global

Reporting Initiative (GRI), Sustainability Reporting

Guidelines

Organizational Units

Covered

From

2012, the scope of coverage was extended to all

consolidated subsidiaries.

| Consolidated Subsidiaries | Other Subsidiaries and Affiliates | |

|---|---|---|

| Japan | KOKUYO Co., Ltd. | KOKUYO K Heart Co., Ltd., Heartland Co., Ltd., IWAMI Paper Industry Co., Ltd., KOKUYO Hokkaido Sales Co., Ltd., KOKUYO Tohoku Sales Co., Ltd., KOKUYO Kitakanto Sales Co., Ltd., KOKUYO Tokai Sales Co., Ltd., KOKUYO Hokuriku-Niigata Sales Co., Ltd. , KOKUYO Sanyo-Shikoku Sales Co., Ltd. |

| Kaunet Co., Ltd., KOKUYO Marketing Co., Ltd., KOKUYO Supply Logistics Co., Ltd., KOKUYO Logitem Co., Ltd., KOKUYO Product Shiga Co., Ltd., KOKUYO MVP Co., Ltd., LmD International Co., Ltd., Actus Co., Ltd., KOKUYO Finance Co., Ltd, KOKUYO & Partners Co., Ltd. | ||

| Overseas | KOKUYO Vietnam Co., Ltd., KOKUYO Malaysia Sdn. Bhd., KOKUYO (Shanghai) Management Co., Ltd., KOKUYO Commerce (Shanghai) Co., Ltd., KOKUYO Furniture (China) Co., Ltd., KOKUYO Design Consultants (Shanghai) Co., Ltd., KOKUYO International Asia Co., Ltd., KOKUYO International (Malaysia) Sdn Hbd, KOKUYO Vietnam TRADING Co.,Ltd., Kokuyo Camlin Limited | KOKUYO-IK(Thailand) Co., Ltd. |

SWIPE TO VIEW MORE >

Scope of Report: KOKUYO Co., Ltd., 20 consolidated

subsidiaries, and 10 affiliates

KOKUYO

Engineering

& Technology was integrated with KOKUYO Co.,

Ltd. in

July 2019, but there has been no impact on the

environmental performance data disclosed

2021 Results

| Environmental Policy | Goals and Results for 2019 | Evaluation | |

|---|---|---|---|

| Goals | Results | ||

| Prevention of global warming |

Reduction

of CO2

emissions Total year-on-year reduction in volume: +4.2% (Excluding impact of production: -1.5%) |

+6.2% (Excluding impact of production: -2.3%) |

× |

| Reduction of unit energy consumption Year-on-year reduction: -1.0% | Per unit of sales: +0.8% | × | |

| Resource Conservation and Recycling |

Improve

recycling rate in relation

to total waste volume • Business offices: 96.6% and over • Construction sites: 82.2% and over |

Business offices: 97.4% |

o |

| Construction sites: 80.7% | × | ||

| Procurement, development, and provision of eco-friendly products | Maintain eco x zero | Maintained | o |

| Information disclosure and communication | Publication of CSR report 2021 | Publication of CSR report 2021 | o |

| Environmental management | ISO 14001: Regular inspection in 2015 |

Regular

inspection results • Strong point: 0 cases • Good points: 16 cases • Matters pointed out for improvement: 0 cases • Opportunities for improvement: 32 cases |

o |

*1 Targets are applicable to the following

companies:

KOKUYO Co., Ltd.; Kaunet Co., Ltd.;

KOKUYO Marketing Co., Ltd.; KOKUYO Engineering &

Technology Co., Ltd.; KOKUYO Supply Logistics Co.,

Ltd.;

KOKUYO Logitem Co., Ltd.; KOKUYO Product Shiga Co.,

Ltd.; KOKUYO MVP Co., Ltd.; KOKUYO K Heart Co.,

Ltd.;

KOKUYO VIETNAM Co., Ltd.; KOKUYO (MALAYSIA) Sdn.

Bhd.;

and KOKUYO-IK (THAILAND) Co., Ltd.

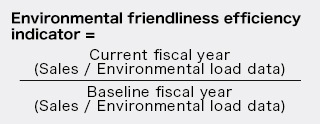

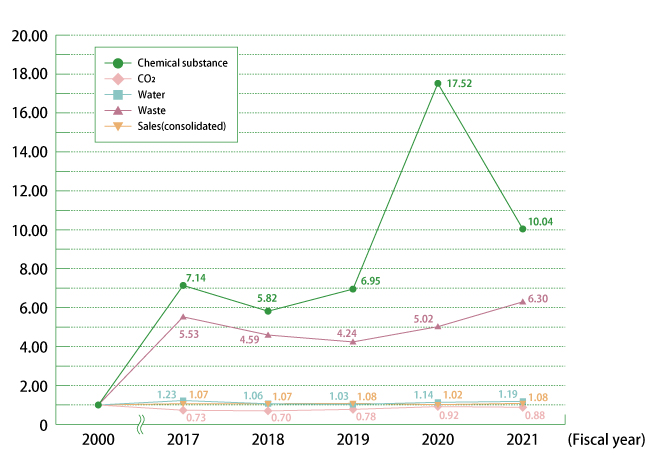

Environmental Friendliness Efficiency Indicators

The KOKUYO Group designates unique environmental friendliness efficiency indicators as indices to comprehensively evaluate financial performance and impact on the global environment.

These indicators show the extent to which products and services are being offered to society with respect to specific environmental load and correspond to the following four items.

1. CO2 emissions

2.

Final

waste disposal

3. Usage of

chemical

substances subject to PRTR

regulations

4. Water usage

Using fiscal 2000 as the baseline for each indicator, the progress status for each fiscal year can be determined.

Environmental Friendliness Efficiency Indicators

Scope of Report: KOKUYO

Co.,

Ltd., 20 consolidated subsidiaries, and 10

affiliates

KOKUYO Engineering & Technology

was

integrated with KOKUYO Co., Ltd. in July 2019, but

there

has been no impact on the environmental performance

data

disclosed

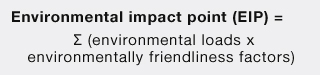

JEPIX

JEPIX (Japan Environmental Policy Priorities Index) is a method of quantifying the individual amount of different types of environmental loads, such as greenhouse gas emissions and air pollutants, as single indicators called Environmental Impact Points (EIP). The EIP is calculated by multiplying the environmental load of each environmentally harmful chemical by the integrated coefficient, which is calculated from the ratio between Japan’s environmental policy target and the actual amount of emissions (environmental friendliness factor), and then obtaining the sum total of them all.

JEPIX

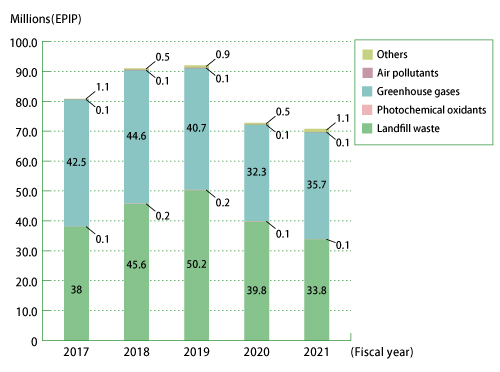

Global Warming Preventive Measures

CO2 Emission Transitions

* Electricity-based emission factors are calculated using the basic emission factors of the relevant electrical power companies for each given year

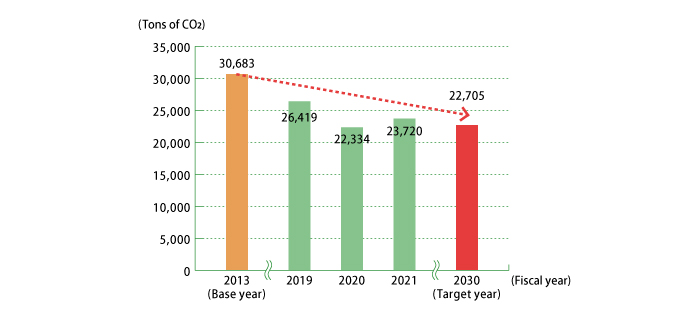

CO2 emission transitions

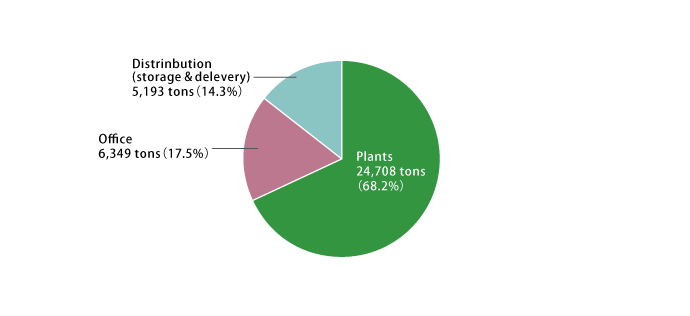

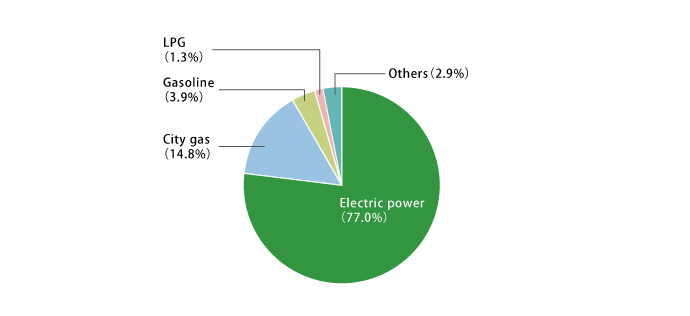

CO2 emission by source

* Market-based

CO2 emission by source

* Market-based

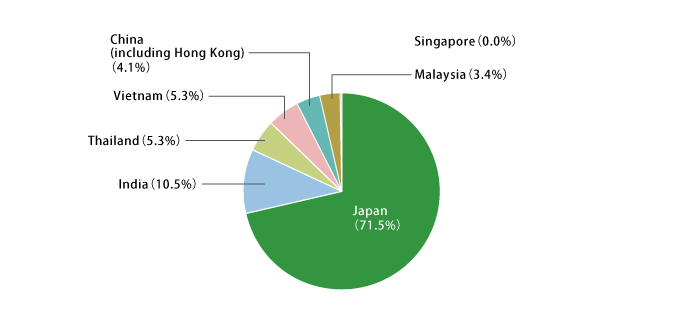

CO2 emissions by country

* Calculations were made according to the standard electrical power emission factors of each country (location-based).

CO2 emission by country

| Tons of CO2 emissions | Percentage of total | |

|---|---|---|

| Japan | 26,087 | 71.5% |

| India | 3,831 | 10.5% |

| Thailand | 1,943 | 5.3% |

| Malaysia | 1,921 | 5.3% |

| Vietnam | 1,483 | 4.1% |

| China (including Hong Kong) | 1,224 | 3.4% |

| Singapore | 5 | 0.0% |

| Total | 36,494 | 100.0% |

SWIPE TO VIEW MORE >

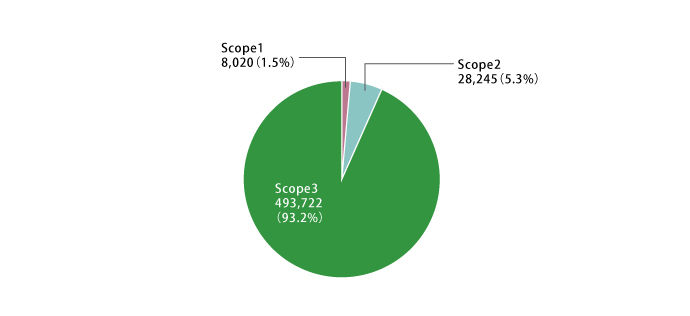

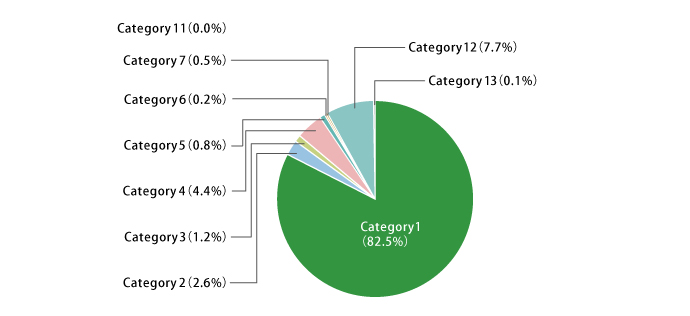

Scope 3 categories and emissions

| Category | Applicable/ Not applicable | Reason for Non-applicability | Scope 3 Emissions | As Percentage of Total | As Percentage of Total Emissions | |

|---|---|---|---|---|---|---|

| Category 1 | Purchased products / services | Applicable | - | 407,446 | 82.5% | 76.9% |

| Category 2 | Capital goods | Applicable | - | 12,736 | 2.6% | 2.4% |

| Category 3 | Fuel not included in Scope 1 or 2 and energy-related activities | Applicable | - | 5,938 | 1.2% | 1.1% |

| Category 4 | Shipping and delivery (upstream) | Applicable | - | 21,625 | 4.4% | 4.1% |

| Category 5 | Waste materials generated by businesses | Applicable | - | 4,037 | 0.8% | 0.8% |

| Category 6 | Business trips | Applicable | - | 887 | 0.2% | 0.2% |

| Category 7 | Commuting by workers | Applicable | - | 2,338 | 0.5% | 0.4% |

| Category 8 | Leased assets (upstream) | Not applicable | Included in Scope 1 / 2 | - | 0.0% | 0.0% |

| Category 9 | Shipping and delivery (downstream) | Not applicable | Included in Category 4 | - | 0.0% | 0.0% |

| Category 10 | Processing of sold products | Not applicable | KOKUYO is a manufacturer of completed products and does not deal with intermediate products | - | 0.0% | 0.0% |

| Category 11 | Use of sold products | Applicable | - | 112 | 0.0% | 0.0% |

| Category 12 | Discarding of sold products | Applicable | - | 37,392 | 7.7% | 7.2% |

| Category 13 | Leased assets (downstream) | Applicable | - | 671 | 0.1% | 0.1% |

| Category 14 | Franchises | Not applicable | No franchises | - | 0.0% | 0.0% |

| Category 15 | Investments | Not applicable | No investments | - | 0.0% | 0.0% |

| Total | - | - | - | 493,722 | - | - |

SWIPE TO VIEW MORE >

Greenhouse gases emitted by the supply chain (by scope) (Tons of CO2 )

Greenhouse gases emitted by the supply chain (for Scope 3)

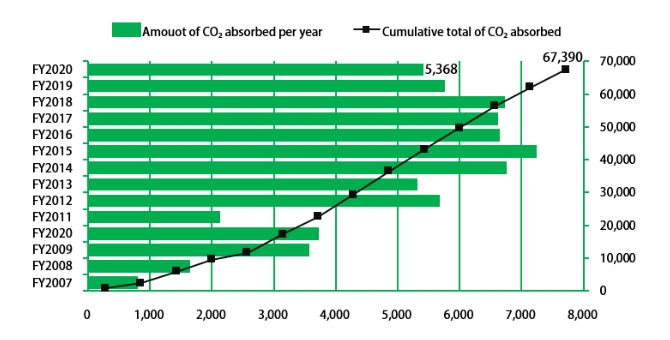

Amount of CO2 absorbed by Yui no Mori

Amount of CO2 absorbed by Yui no Mori (cumulative total)

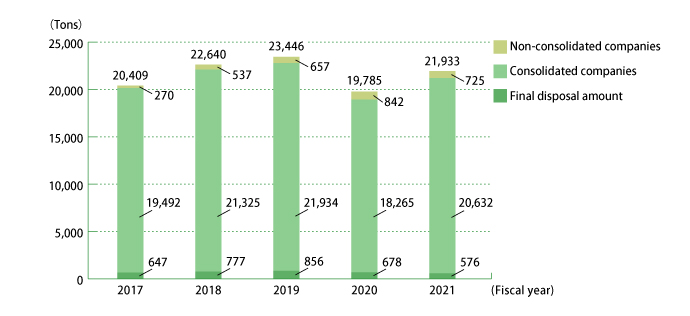

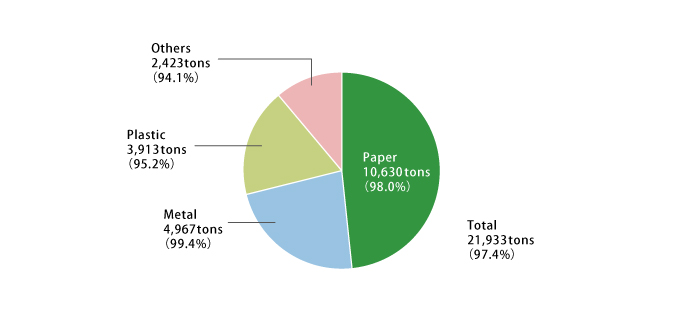

Resource Saving and Recycling

Waste Materials: Recycling and Final Disposal Amounts

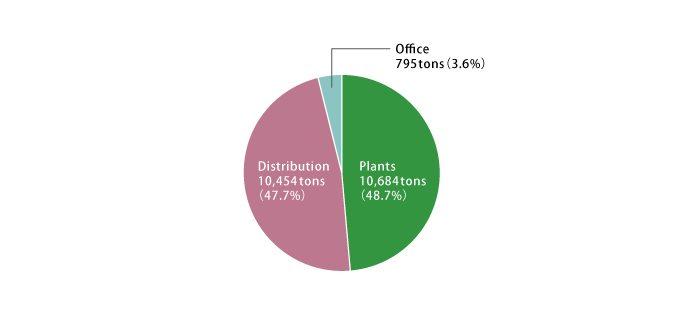

Waste Materials by Activity

Waste material types (Recycling rate in brackets)

Emissions by Country

Chemical Substances Subject to PRTR Law

| Official No. | Chemical name | Vol. handled (kg) | Vol. Released | Vol. Treated (kg) | Vol. Consumed (kg) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Vol. Released into Air (kg) | Vol. Released into Public Bodies of Water (kg) | Vol. Released into Sewers (kg) | Vol. Sent to Landfill (kg) | Sub-total (kg) | |||||

| 1 | Zinc compounds (water-soluble) | 465.6 | 0.0 | 0.0 | 0.0 | 465.6 | 465.6 | 0.0 | 0.0 |

| 20 | 2-aminoethanol | 221.2 | 0.0 | 0.0 | 0.0 | 221.2 | 221.2 | 0.0 | 0.0 |

| 30 | Linear Alkyl Benzene Sulfonic Acid and its salts (LAS) | 195.0 | 0.0 | 0.0 | 0.0 | 195.0 | 195.0 | 0.0 | 0.0 |

| 53 | Ethylbenzene | 15.0 | 15.0 | 0.0 | 0.0 | 0.0 | 15.0 | 0.0 | 0.0 |

| 57 | Ethylene glycol monoethyl ether | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 71 | Ferric chloride | 11,285.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 11,285.0 |

| 80 | Xylene | 18.5 | 18.3 | 0.0 | 0.0 | 0.0 | 18.3 | 0.0 | 0.2 |

| 82 | Silver and its water-soluble compounds | 1.5 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.5 | 0.0 |

| 125 | Chlorobenzene | 17.1 | 12.1 | 0.0 | 0.0 | 0.3 | 12.4 | 0.0 | 4.7 |

| 134 | Vinyl acetate | 192.7 | 19.3 | 2.9 | 1.8 | 11.6 | 35.7 | 0.0 | 157.0 |

| 235 | Water-soluble salts of bromic acid | 440.7 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 440.7 | 0.0 |

| 300 | Toluene | 167.1 | 21.2 | 0.0 | 0.1 | 6.7 | 27.9 | 0.0 | 139.2 |

| 302 | Naphthalene | 6.4 | 0.0 | 0.0 | 0.0 | 0.2 | 0.2 | 0.0 | 6.2 |

| 309 | Nickel compounds | 45.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 45.6 | 0.0 |

| 354 | Di-n-butyl phthalate | 68.0 | 0.0 | 0.0 | 0.0 | 4.6 | 4.7 | 0.0 | 63.3 |

| 392 | N-hexane | 35.2 | 35.2 | 0.0 | 0.0 | 0.0 | 35.2 | 0.0 | 0.0 |

| 403 | Benzophenone | 15.9 | 0.0 | 0.0 | 0.0 | 0.8 | 0.8 | 0.0 | 15.1 |

| 407 | Poly(oxyethylene)alkyl ether(alkyl C=12-15) | 704.6 | 0.0 | 0.0 | 14.4 | 454.9 | 469.3 | 4.8 | 230.4 |

| 410 | Poly(oxyethylene)nonylphenyl ether | 18.3 | 0.0 | 0.0 | 0.0 | 0.9 | 0.9 | 0.0 | 17.4 |

| 412 | Manganese and its compounds | 17.3 | 0.8 | 0.0 | 0.0 | 6.1 | 6.9 | 0.0 | 10.4 |

| 448 | Methylenebis(4,1-cyclohexylene)diisocyanate | 445.3 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 445.3 |

| 453 | Molybdenum and its compounds | 166.1 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 166.1 |

| Total | 14,541.9 | 121.9 | 2.9 | 16.3 | 1,367.9 | 1,509.0 | 492.6 | 12,540.2 | |

SWIPE TO VIEW MORE >

* The volume of PRTR Law Class I

Designated Chemical Substances that

were

used, handled, released,

transferred,

disposed, recycled, and consumed by

the

business establishments (in Japan)

subject to notification under the

PRTR

Law. For the calculation methods,

see

the Ministry of the

Environment/Ministry

of Economy, Trade and

Industry’s

PRTR Release Estimation Methods

Manual,

version 4.1 (March 2011).

*

“Volume

treated” refers to those PRTR

designated substances that were

treated

on site by incineration,

neutralization,

breaking down, reactive process,

etc.

* “Volume

consumed”

refers to the volume of PRTR

designated

substances that were modified by way

of

reaction into other substances,

incorporated into products or moved

off-site with products.

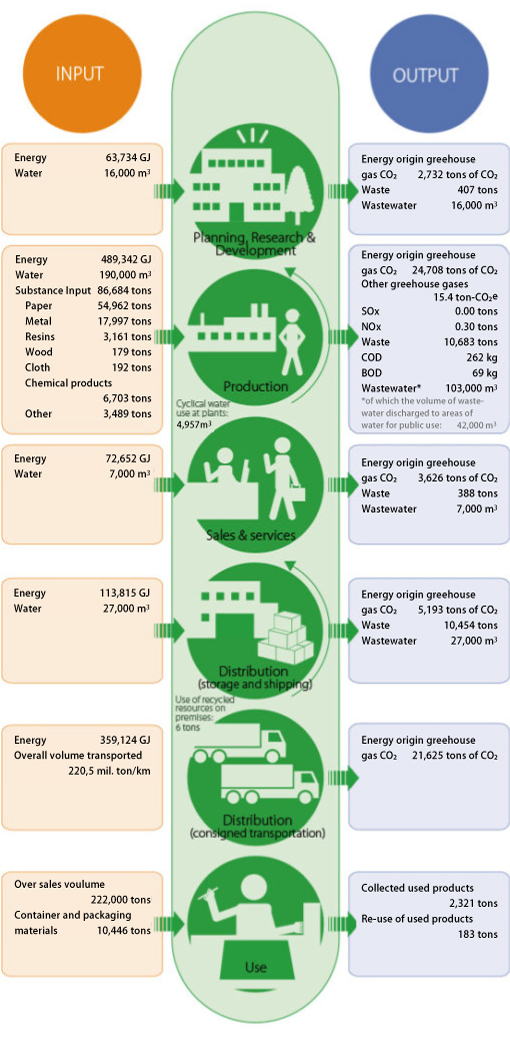

Environmental Load Material Flow

Input items

| Indicator | Unit | Calculation method |

|---|---|---|

| Volume of energy used | GJ | Power, gas (city gas, LPG, natural gas), oil (gasoline, light oil, kerosene, fuel oil A), heat (hot water, cold water) The power unit calorific values are the daytime and nighttime power values stated in the Enforcement Regulations of the Act on the Rational Use of Energy (effective from April 1, 2008). The unit calorific values of gas, oil, and heat are those values presented in the Greenhouse Gas Emission Calculation and Reporting Manual, Ver. 4.8 (Jan 2022 (Ministry of the Environment, Ministry of Economy, Trade and Industry). |

| Water | 1,000 m3 | Tap water, water for industrial use |

| Substance Input | Tons | The volume of raw materials used to manufacture KOKUYO products |

| Overall Sales Volume | 10,000 tons | Data from furniture and stationery products |

| Container and Packaging Materials | Tons | The volume of packaging materials used to package products |

SWIPE TO VIEW MORE >

Output Items

| Indicator | Unit | Calculation method |

|---|---|---|

| CO2 Emissions from Energy Use | Tons of CO2 |

CO2

emissions

from the use

of

electricity,

gas, oil,

and heat. *See

Global

Warming

Preventive

Measures.

Coefficients

based on the

Act on

Promotion of

Global

Warming

Countermeasures

(adjusted

emission

coefficients

for each

power

company for

fiscal 2019

and 2020)

were used to

calculate

the

CO2

emissions

from power

consumption

in

Japan. Coefficients for each country covered on the GHG Protocol website, released by the World Business Council For Sustainable Development (WBCSD) and the World Resources Institute (WRI), were used to calculate the CO2 emissions from power consumption overseas. Values presented in the Greenhouse Gas Emission Calculation and Reporting Manual, Ver. 4.8 (Jan 2022) (Ministry of the Environment, Ministry of Economy, Trade and Industry) were used to calculate CO2 emissions from the use of gas, oil, and heat. The ton/kilo method and the fuel consumption method were both used to calculate the distribution (consigned transportation) CO2 emissions. |

| Other Greenhouse Gases | Tons of CO2e | Emissions of greenhouse gases (CO2, CH4, N2O) related to production activities, (in Japan), but excluding such emissions from energy sources, have been converted to a CO2 basis. Emission coefficient values were taken from the Ministry of the Environment and the Ministry of Economy, Trade and Industry's Greenhouse Gas Emission Calculation and Reporting Manual, Ver. 4.8 (Jan 2022). |

| SO2">x, NO2">x | Tons | Emissions from smoke- and soot-producing facilities at manufacturing plants (in Japan) |

| Waste | Tons |

The

volume of

discharged

waste

(emissions)

is the total

amount of

waste and

valuable

substances

discharged

from

business

establishments. The recycle volume is the total of the volume of discharged waste (emissions) that has been recycled through material or thermal recycling, and the volume of valuable substances. The final waste volume is the combined total of the recycling residue and the volume of waste directly disposed of in landfills, out of the total volume of discharged waste (solid waste). *See Resource Saving and Recycling. If industrial waste has been calculated by cubic measurement, conversion factors (reference) for converting cubic measurements of industrial waste into weights as stated in a notice released by the Ministry of the Environment (December 27, 2006; Env. Ind. Waste Issue No. 061227006) were used. |

| Wastewater | 1,000 m3 | Wastewater discharged to areas of water for public use and into the sewage system |

| COD, BOD | kg | Of plants in Japan, the volume of effluent discharged to areas of water for public use by plants with a legal obligation to measure water quality |

SWIPE TO VIEW MORE >

Other items

| Indicator | Unit | Calculation method |

|---|---|---|

| Overall Transportation Volume | Tons/km | The total of the following outsourced transportation volumes: total domestic transportation in Japan including the transportation of furniture products, store fixtures, stationery products, transportation of catalog sales by Kaunet, and transportation of Actus products; and transportation of products between overseas sites and within Malaysia. |

| Cyclical Water Use at Plants | m3 | The volume of water used in a cyclical way (i.e. recycled) on business premises |

| Cyclical Resource Use on Sitest | Tons | The volume of recycled resources, such as packaging materials, on the business premises of KOKUYO Logitem Co., Ltd. and KOKUYO Supply Logistics Co., Ltd. |

| Collected Used Products | Tons | The volume of used products collected from customers by KOKUYO Logitem Co., Ltd. |

| Re-use of Used Products | Tons | The volume of re-used products from the used products collected from customers by KOKUYO Logitem Co., Ltd. |

SWIPE TO VIEW MORE >

Environmental Accounting

Environmental Accounting (Unit: Ten thousand of yen)

| Item | Environment-related Investments | Costs | Effects | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2019 | 2020 | 2021 | 2019 | 2020 | 2021 | 2019 | 2020 | 2021 | 2019 | 2020 | 2021 | |

| Pollution prevention | 0 | 0 | 690 | 5,549 | 3,963 | 1,532 | 0 | 0 | 0 | 5,549 | 3,963 | 1,532 |

| Global warming prevention | 6,477 | 11,842 | 10,785 | 11,642 | 8,363 | 8,200 | ▲2,052 | ▲1,923 | ▲2,160 | 9,589 | 6,440 | 6,040 |

| Resource saving and recycling | 0 | 0 | 0 | 34,826 | 42,117 | 54,265 | ▲19,359 | ▲15,315 | ▲24,564 | 15,466 | 26,802 | 29,701 |

| Procurement and provision of eco-friendly products | 0 | 0 | 0 | 4,016 | 3,181 | 3,583 | 0 | 0 | 0 | 4,016 | 3,181 | 3,583 |

| Survey and research into environmental technology | 0 | 0 | 0 | 167 | 184 | 160 | 0 | 0 | 0 | 167 | 184 | 160 |

| Environmental communication | 0 | 0 | 0 | 1,836 | 1,442 | 1,623 | 0 | 0 | 0 | 1,836 | 1,442 | 1,623 |

| Setting up management structures | 0 | 0 | 0 | 6,551 | 5,851 | 6,369 | 0 | 0 | 0 | 6,551 | 5,851 | 6,369 |

| Environmental damage response | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total | 6,477 | 11,842 | 11,475 | 64,586 | 65,100 | 75,732 | ▲21,412 | ▲17,237 | ▲26,723 | 43,175 | 47,863 | 49,009 |

SWIPE TO VIEW MORE >

Breakdown of economic effects

| Item | Content of countermeasures | 2019 | 2020 | 2021 |

|---|---|---|---|---|

| Global warming prevention | Effects of introducing energy-saving facilities | ▲1,043 | ▲703 | ▲1,124 |

| Effects of solar power generation | ▲980 | ▲1,009 | ▲978 | |

| Effects of improving operations | ▲29 | ▲211 | ▲58 | |

| Resource saving and recycling | Cost reductions achieved through the use of recycled items | ▲19,318 | ▲15,313 | ▲24,561 |

| Waste Reduction | ▲2 | ▲2 | ||

| Cost reductions achieved through the promotion of recycling | ▲41 | 0 | ||

| Total | ▲21,412 | ▲17,237 | ▲26,723 |

SWIPE TO VIEW MORE >

Sites with ISO 14001 Certification

| No. | Company Name | Site Name |

|---|---|---|

| 1 | KOKUYO | Head Office (including XT and WS) |

| 2 | Tokyo Shinagawa Office | |

| 3 | Tokyo Shinagawa SST Office | |

| 4 | Tokyo Kasumigaseki Office | |

| 5 | Nagoya Office | |

| 6 | Osaka Umeda Office | |

| 7 | Mie Factory | |

| 8 | Shibayama Factory | |

| 9 |

KOKUYO K Heart |

Head Office |

| 10 |

KOKUYO MVP |

Tottori Factory |

| 11 | Aoya Factory | |

| 12 |

KOKUYO Product Shiga |

Head Office |

| 13 |

KOKUYO Logitem |

Head Office |

| 14 | Sendai Distribution Center | |

| 15 | Gunma Distribution Center | |

| 16 | Central Japan Delivery and Distribution Center | |

| 17 | Central Japan Delivery Center | |

| 18 | Shin Chiba Distribution Center | |

| 19 | Shiga Distribution Center | |

| 20 | Mie Distribution Center | |

| 21 | Ina Distribution Center | |

| 22 | Chubu Delivery and Distribution Center | |

| 23 | Toyama Distribution Center | |

| 24 | Fujiwara Distribution Center | |

| 25 | Komono Distribution Center | |

| 26 | Kansai Delivery and Distribution Center | |

| 27 | Okayama Distribution Center | |

| 28 | Kyushu Distribution Center | |

| 29 |

KOKUYO Supply Logistics |

Head Office |

| 30 | Ibaraki Distribution Center | |

| 31 | Metropolitan Area Integrated Distribution Center | |

| 32 | Kyushu Integrated Distribution Center | |

| 33 | Chubu Integrated Distribution Center | |

| 34 | Shiga National Distribution Center | |

| 35 | Kinki Integrated Distribution Center | |

| 36 | Osaka Nanko Distribution Center | |

| 37 | Sapporo Distribution Center | |

| 38 | Fukuoka Distribution Center |

SWIPE TO VIEW MORE >

| No. | Company Name | Site Name |

|---|---|---|

| 39 | Kaunet | Head Office |

| 40 | Tokyo Shinagawa Office | |

| 41 |

KOKUYO Marketing |

Head Office |

| 42 | Tachikawa Office | |

| 43 | Chiba Office | |

| 44 | Saitama Office | |

| 45 | Yokohama Office | |

| 46 | Nagano Office | |

| 47 | Matsumoto Office | |

| 48 | Nagoya Office | |

| 49 | Shizuoka Office | |

| 50 | Umeda Office | |

| 51 | Kyoto Office | |

| 52 | Kobe Office | |

| 53 | Wakayama Office | |

| 54 | Hiroshima Office | |

| 55 | Yamaguchi Office | |

| 56 | Matsue Office | |

| 57 | Fukuoka Office | |

| 58 | Nagasaki Office | |

| 59 | Miyazaki Office | |

| 60 | Kagoshima Office | |

| 61 | Kumamoto Office | |

| 62 | Oita Office | |

| 63 | Okinawa Office | |

| 64 |

KOKUYO (Malaysia) |

Head Office |

| 65 |

KOKUYO-IK Thailand |

Head Office |

| 66 |

KOKUYO Camlin |

PATALGANGA PLANT |

| 67 | TARAPUR PLANT | |

| 68 | SAMBA PLANT | |

| 69 |

KOKUYO Commerce (Shanghai) |

Head Office |

| 70 | Shanghai Factory | |

| 71 | Beijing Office |

SWIPE TO VIEW MORE >