Providing Peace of Mind and Safety to Customers

Social: Providing Peace of Mind and Safety to Customers

Business Concepts

KOKUYO always develops new products and services from the perspectives of customers, and, without being satisfied with the present conditions, we continue to improve the safety and quality of our entire product line and services.

Systems

Attainment of ISO 9001 (Quality Management System) Certification by All Companies

KOKUYO Quality Pledge

We shall continually aim to

delight and win the trust of customers by providing products and services that

help people work, play, and learn better.

- We shall endeavor to develop products that exceed customer expectations in every way

- We shall endeavor to ensure product safety and to raise the bar on product quality

- We shall comply with legal requirements and fulfill our corporate social responsibility

- We shall listen to customers and incorporate their feedback into the development cycle

- We shall update our management system in response to changes in the business landscape

January 1, 2019

Hidekuni Kuroda

President and CEO

* For stationery, standardization covers only KOKUYO-brand products. For office supplies (made by Kaunet), it covers only Kaunet-brand products.

Registration certificate number: JQA-2029

Registered business: KOKUYO Co., Ltd.

Scope of registered activities:

- Design, development and manufacture of office furniture

- Purchase and sale of office furniture

- Design, development, manufacture and construction of furniture used in public facilities

- Design, development, manufacture and construction of building materials

- Design and development of stationery products

- Purchase and sale of stationery products

- Planning, development, purchase and sale of products handled by Kaunet

Relevant business / production sites:

- Furniture Business Division: Head Office, Mie Plant, Shibayama Plant, Tokyo Shinagawa Office and Umeda Office

- Stationery Business Division; Head Office, Tokyo SST Office, Ibaraki Delivery Center, Shiga NDC and Osaka Nanko Delivery Center

- Kaunet Co., Ltd.: Tokyo Shinagawa SST Office

*Current as of April 15, 2022

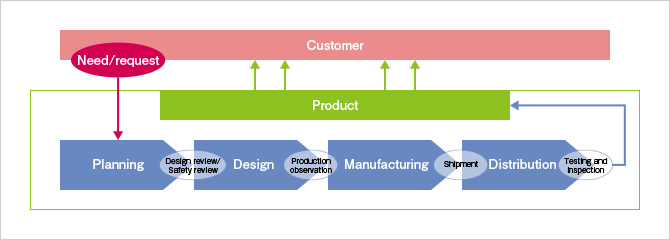

Quality assurance for stationery

In order to deliver quality that our customers can trust, we have taken steps to systematically build, operate and improve our systems for quality assurance, covering planning, design, manufacturing, and distribution.

1. Continually improving quality assurance

To ensure

that customers can use our products safely and securely, we continually

improve our system for quality assurance by updating the key processes (design

review, safety review, production observation, chemical safety management,

legal compliance). We also perform risk assessments to identify and mitigate

potential risks.

2. Inspection and testing based on international

standards

When testing and inspecting products, we apply

international standards. We evaluate testing and inspection processes with a

view to improving the country-specific standards. Additionally, we endeavor to

do more to catch defects before the product is sold to customers.

3. Responding to customer complaints quicker and more

accurately

It is not enough for a product to be objectively

safe; the customer must feel reassured that it is so. This is especially true

in today’s world, where people have a plethora of information at their

fingertips. Accordingly, we need to respond all the quicker and all the more

accurately to customer complaints. To that end, we have established clear and

standardized protocols, tools, and criteria for responding to such incidents.

Such standardization streamlines the response process and minimizes

inconsistencies in responses.

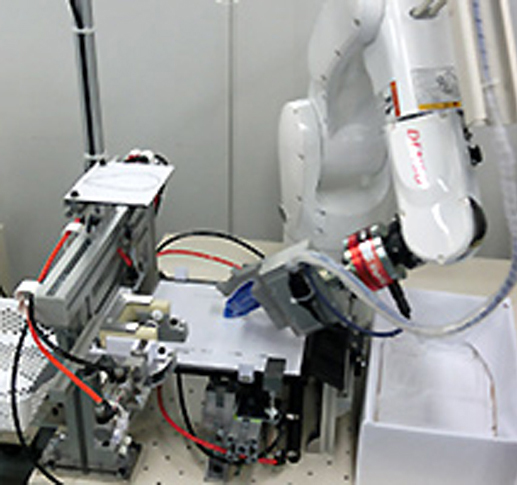

4. Testing for quality, testing for value

We have

always performed thorough quality evaluations when updating products or

releasing new ones, and we recently introduced robotics to enhance the

reproducibility and accuracy of the testing. For a product to satisfy

customers, it must not only be reasonably priced and reliable; it must also

have a wow-factor. We have started quantifying the extent to which a product

has this.

Robotics technology for quality testing

Quality assurance for furniture

Our furniture businesses attained ISO 9001 certification in 1997. Since then, we have standardized the marketing, planning, design, production, and installation processes for furniture. We use a PDCA cycle to ensure that we always provide products and services that are tailored to the changing ways in which people work, study, and live. We continually strive to improve our manufacturing, delivery, and installation. We listen to feedback from customers and use this feedback to inform and guide our continual-improvement activities.

1. Setting high standards for craftsmanship

When developing a

product, we assess safety and functionality using a variety of metrics. As well as

measuring the product against the Japanese Industrial Standards and other industry

standards, we measure it against our own standards, which are even higher and which we

update annually.

2. Dealing with defects

When a customer finds a defect in one

of our products, we inform the relevant personnel without delay. As well as

investigating the cause for the defect, we make the necessary improvements in the

product or manufacturing process to prevent a similar defect.

If there is a

serious safety issue, the Risk Compliance Committee will determine the response. To

limit the damage, we will notify the relevant authorities and issue notices on our

website and in newspapers and other media to alert consumers.

3. Public notices concerning safety or quality

issues

We use our website to alert consumers about safety or

quality issues with our products.

Quality assurance for Kaunet’s products

Kaunet has a huge lineup that includes stationery, office supplies, food and drink, home appliances, gifts, medical equipment, shop equipment, order-made business cards and seals/stamps, and office furniture. The business has around a thousand suppliers. It also has its own premium brand, Kaukore, which emphasizing workplace productivity. At least 5,200 products are sold under this brand. Kaunet always strives to develop useful products based on ideas from the user’s perspective. To ensure that its products are safe and command confidence, Kaunet works together in the value chain to improve not only the quality of its goods but also the customer service at call centers and delivery.

1. Kaukore, Kaunet’s premium series

When developing a product, we assess safety and functionality using a variety of metrics. As well as measuring the product against the Japanese Industrial Standards and other industry standards, we measure it against our own standards, which are even higher and which we update annually.

2. Hearing it straight from the customers : Monitor

Kaunet

Kaunet operates Monitor Kaunet, a web community through

which it interacts with customers directly. Monitor Kaunet helps Kaunet

understand the concerns and problems customers experience on a daily basis,

providing inspiration for product ideas.

*Website content Japanese language only

3. A call center for hearing customer feedback on a daily

basis

As well as Monitor Kaunet, Kaunet operates a call

center. The feedback obtained over the phone leads to improvements to existing

products and services as well as to new products. Kaunet shares the feedback

throughout the entire company so that it can improve its products and

services.

4. Trustworthy delivery service

Customers can order

Kaunet products on the company’s website or from its printed catalog. Goods

are delivered on the same day or on the following day at the latest. An

assembly service is also available for bulky furniture and items that are

tricky to assemble. For this service, delivery staff trained in furniture

assembly will assemble and install the item in the customer’s office or home

and take all the packaging away with them.

Initiatives in 2021

Annual Training to Improve the Skills of the Members of the QMS Internal Audit Team

We conduct internal audits every year in our quality management system (QMS) activities. The purpose of those audits is to evaluate whether the QMS is producing results as intended. The members of the internal audit team appointed by the organization evaluate whether products, services and the processes that produce those comply with the requirements in internal audits. If there is a problem, the identified organization promptly strives to correct it. KOKUYO considers these internal audits to be a very important measures to enhance customer satisfaction. Accordingly, we provide education and training every year so that members of the internal audit team improve their skills to be able to conduct effective internal audits.