ENVIRONMENTALLY-FRIENDLY PRODUCTS AND SERVICES

Green Procurement, Green Development, Green Supply Environmentally-Friendly Products and Services

Basic Concepts

The KOKUYO Group is working on new environmental technologies and green procurement in order to reduce the environmental load over the entire life cycle of its products.

Systems

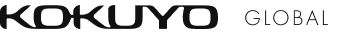

Eco-Batsu initiative, Circular Business Guidelines

The KOKUYO Group started using the Eco-Batsu (“no good”) mark for products in the 2008 General Catalog. This mark is used for group products that are not sufficiently environmentally friendly at any stage of their life cycle, including manufacturing, distribution, usage, and disposal. We tasked ourselves with removing the Eco-Batsu mark from all of our products in three years, and this goal was reached in the 2011 General Catalog. We continue to apply the due-diligence system to products in the 2023 General Catalog.

In 2022, we updated the initiative, creating the Circular Business Guidelines. The guidelines are designed to support closed-loop recycling and reduce recycling speed by reinforcing efforts in use, collection, and recycling. They also emphasize communicating with users and the venous industry (companies that turn industrial waste into reusable resources) to promote a shift to genuinely recyclable products and to develop the maintenance and collection services that underpin closed-loop recycling.

Action against plastic pollution

The proportion of plastics among raw materials is not large in the KOKUYO Group. Nevertheless, we are strengthening our efforts to meet the growing international interest in plastic pollution in recent years and the expectations of our consumers and customers.

Plastic recycling initiatives

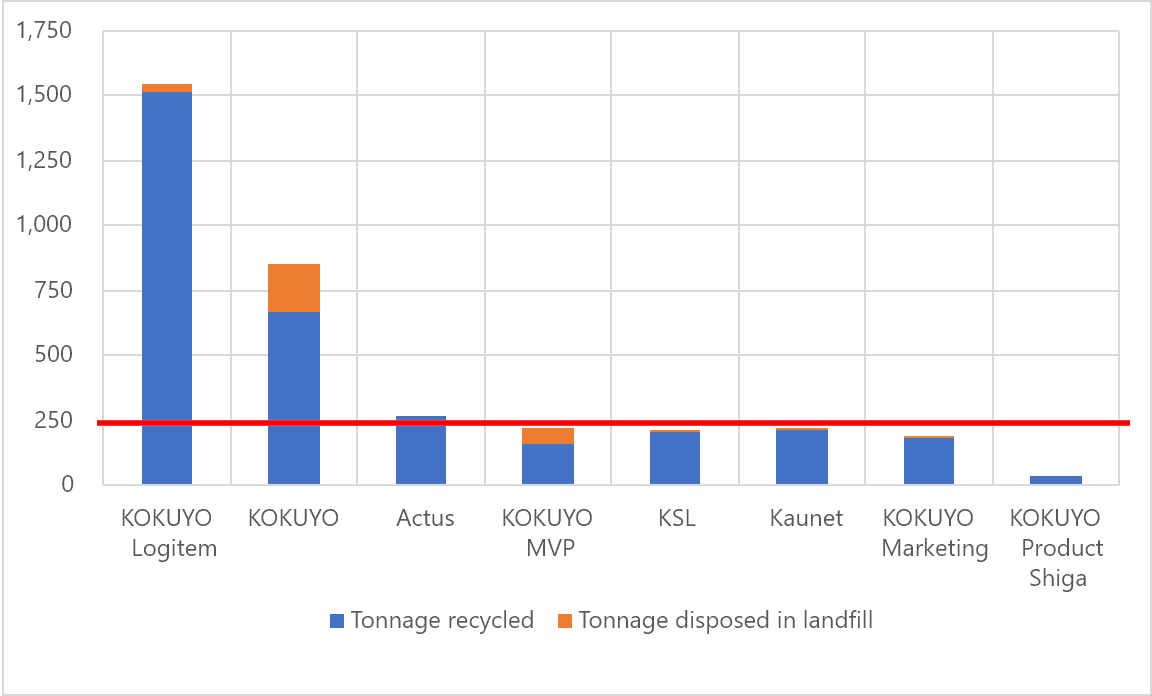

KOKUYO Group generated 3,547 tons of plastic waste between April 2022 and March 2023. Our group’s logistics operations accounted for the largest share, followed by construction and manufacturing operations. We are working to generate less plastic waste, recycle more of the waste, and improve the quality of recycling (by switching from thermal recycling to chemical or material recycling).

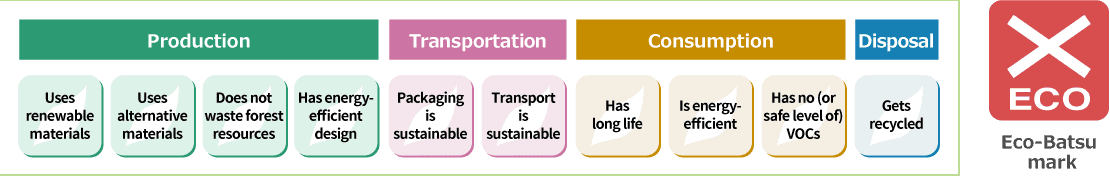

【Plastic waste tonnage by group company】

*1 ton is equal to 1,000 kilograms

Japan’s Act on Promotion of Resource Circulation for Plastics defines as a high-waste-producing business any business that produced more than 250 tons of plastic waste in the previous year.

-

【Plastic waste tonnage by business operation】

*1 ton is equal to 1,000 kilograms, % indicates percentage of plastic waste that was recycled

-

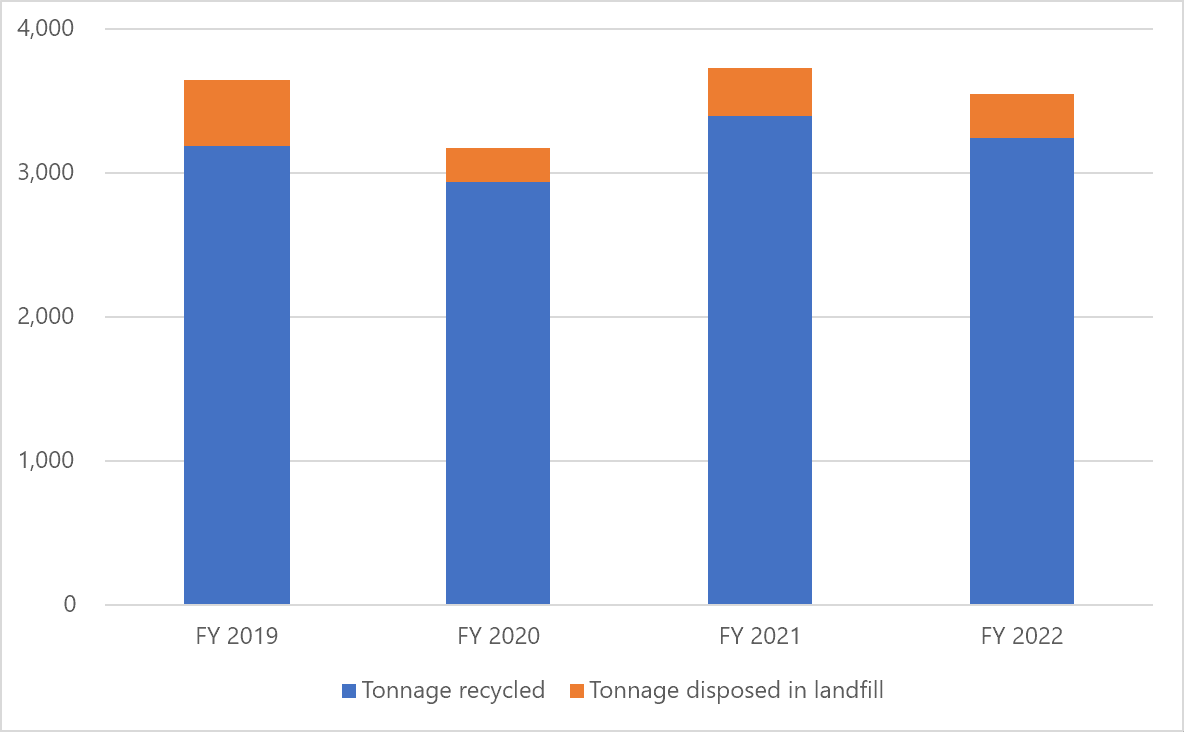

【Inter-year comparison in plastic waste tonnage in Japan】

*1 ton is equal to 1,000 kilograms

The All-Paper series

This is a series of filing products made fully from paper. When it was launched in March 2004, the series received praise for being able to be disposed without having to incur effort to separate into paper, plastic, metal and other materials. With the recent global rise in the problem of ocean plastics, the series is again gaining recognition from the perspective of moving away from plastic. In 2020, we added some more products to the series. One of the new products is a folder with a window which lets you see the contents. Another is a large-capacity flat file.

The All-Paper series is involved in the Plastics Smart Campaign established by Japan’s Ministry of the Environment toward solving the global problem of ocean plastics that supports the advancement of initiatives through the partnership and cooperation of a wide range of entities such as individuals, local governments, NGOs, companies, and research agencies. For example, we are a member of the Japan Clean Ocean Material Alliance (CLOMA), and such membership helps us stay abreast of the latest technological advances in addressing the problem of ocean plastics.

Kaunet’s Initiatives

One of Kaunet’s eco-initiatives is to offer simplified packaging for its deliveries. Moreover, it has switched to environmentally-friendly biomass plastic for all the plastic used in its simplified packaging.

When ordering online, customers are presented with three packaging options: simplified, cardboard, and no-preference. The company has also switched to biomass plastic bags for the plastic bags it uses to deliver its with Kaunet catalogs.

Resource Recycling Initiatives

The Act on Promotion of Resource Circulation for Plastics has served as an impetus for action on plastic recycling: Many companies have started encouraging serving drinks to visitors in paper cartons rather than in plastic bottles. Noting this shift to paper cartons, and noting that the cartons are rarely collected for recycling, Kaunet launched a collect-and-recycle scheme called Loopa in partnership with a beverage company and recycler. In Loopa, Kaunet collects used paper cartons and cups and upcycles them into paper products.

KOKUYO MVP has entered into a contract with a manufacturer that manufactures pallets for distribution made with composite materials. The company is working to recycle the waste plastic generated from its factories into resources through this initiative. KOKUYO Logitem is promoting closed recycling. The company is using a recycling operator to convert the stretch film and cable ties generated from its distribution centers into plastic bags. It then reuses those bags internally.

-

Large-capacity flat file (all paper)

-

Paper folder with window (all paper)

-

The logo for Loopa, Kaunet’s collect-and-recycle scheme

Showing the carbon footprint of our products

In 2010, we started monitoring and publicly disclosing the carbon footprint of products from the time they are produced to the time they are disposed of or recycled. Please refer to the page below for details.

View the carbon footprint of our products (Japanese Only)Using Japanese-made, Locally Produced Materials

As much as 67% of Japan’s landmass is covered by forests. Forests help prevent sediment runoff, contribute to water retention, and absorb CO2. They also provide a renewable resource. However, in much of the country’s man-made forests, which account for 40% of all the forests, these roles are not fully performed due to insufficient forest thinning. In 1998, we started developing furniture products made from timber harvested from forest thinning operations. We released the products to the market in 2000. By making our office products from Japanese timber that was harvested during thinning operations, we create new demand for wood while also contributing to sustainable forestry.

Yuimori

Back in October 2006, we launched the Yui-no-Mori Project in partnership with the Taisho-cho Forestry Association (now the Shimanto-cho Forestry Association) in Kochi Prefecture. More recently, we launched Yuimori, a brand of wooden furniture made from timber harvested in Yui-no-Mori Project. By using Japanese timber, the brand contributes to harmony with nature. Yuimori products feature elegant and impactful designs along with the high quality required for office furniture. They are also designed for sustainable disposal. The products were designed by Keiji Ashizawa, who boasts an extensive design portfolio from architecture to furniture. Furniture experts Tendo Mokko (headquartered in Tendo, Yamagata; represented by Yukio Kato) fabricated the designs, bringing out the timber feel. We contributed our own know-how in office furniture, such as ideas for making a chair comfortable. Through Yuimori, we contribute to greater harmony with nature.

View the Yuimori webpage:https://kokuyo.jp/yuimori

Protocol Counter

In response to the demand for locally sourced materials, we developed a reception desk that uses such materials. Designed by Graf: Decorative Mode Number 3, the product has a crisp, modern feel. It also embodies universal design principles: the table edge has a groove for securing a walking stick or similar items and a grip for wheelchair users.

-

Protocol Counter, winner of the Japan Wood Design Award 2017

-

UU Chair

EF Counter, featuring modesty panels made from locally sourced timber

EF Counter is a series of modular counters that can be rearranged to suit changes in the organization or changes in desired use. With their universal design, the counters are friendly to the elderly and to wheelchair users. While part of the structure is made from standardized materials, the modesty panel is made from timber sourced from the locality in question. This arrangement ensures that the counters are no less functional and versatile than standard counters are. As with Protocol Counter, the table edge has a groove for securing a walking stick or similar items and a grip for wheelchair users.

Protocol Counter serving in the new municipal building of Yamato-Koriyama, Nara

-

Ground floor, waiting area

-

Ground floor, main reception desk

-

Fourth floor, secretariat’s reception desk

In March 2022, we delivered a protocol counter made of Yoshino hinoki cypress for use in Yamato-Koriyama’s new municipal building, which was due to be completed in June 2023. With the new building intended to serve as a new symbol of the municipality, the building would have a welcoming atmosphere, with an interior design that was straightforward, accessible, and employee-friendly. To that end, the interior would feature plenty of local timber, emphasizing harmony between nature and residents. Accordingly, we pitched a reception counter made from Nara timber, emphasizing that this aligned with the interior design. Our pitch proved successful. We will continue pitching furniture that is made from local timber and that is functional, user-friendly, green, in order to encourage the use of (or a shift to) timber in public buildings.