Climate Action

Climate Action for the Global Environment

The KOKUYO Group strengthens activities to ease global warming (measures for the reduction and absorption of CO2 emissions) with a view to achieve a low carbon society.

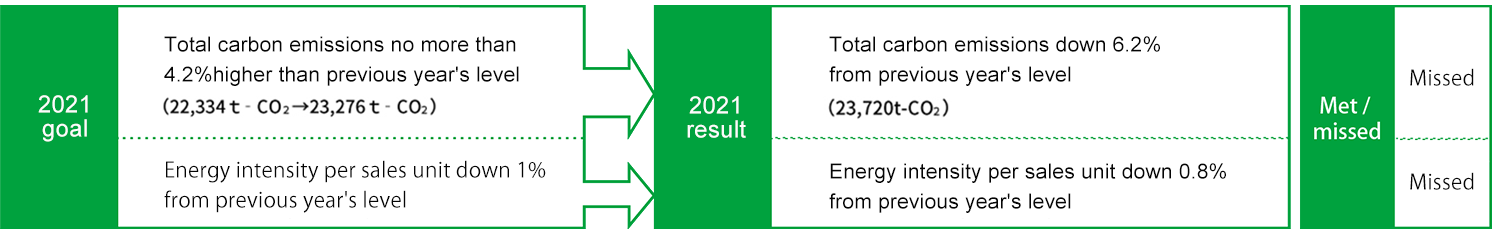

Summary for 2021

In 2021, a total of 23,720 tons of CO2 was emitted by our consolidated subsidiaries in Japan*1 and by our disability-friendly subsidiaries, KOKUYO K Heart and Heartland. That was an increase of 1,386 tons from the previous year (+6.2% year on year). The change in emission coefficients*2 accounts for a reduction of 242 tons among the change. According to our estimates, the actual increase was 1,628 tons and the breakdown was as follows: although we cut 341 tons by improving operations and 171 tons by improving facilities and equipment, there was an increase by 2,140 tons by consolidating manufacturing operations. The changes for offices, production sites, and distribution channels are as follows.

Offices

There was an increase by 493 tons compared to the previous year (increase excluding the impact of emission coefficients: 470 tons). The breakdown was as follows: there was an increase by 568 tons compared to the previous year when we closed offices due to COVID-19, a reduction by 36 tons thanks to telecommuting, and a reduction by 62 tons from updating air conditioners and switching to LED lighting.

Production Sites

There was an increase by 1,135 tons compared to the previous year (increase excluding the impact of emission coefficients: 1,261 tons). The breakdown was as follows: there was an increase by 1,601 tons compared to the previous year when we adjusted production due to COVID-19, a reduction by 293 tons thanks to improvements in operations (shortening of the time to replace product models and thoroughly implementing operation rules for production equipment, etc.) and a reduction by 47 tons due to installing energy-saving equipment (converting equipment to inverters and switching to LED lighting, etc.)

Distribution Channels (Storage and Shipping)

There was a reduction by 242 tons compared to the previous year (reduction excluding the impact of emission coefficients: 103 tons). The breakdown was as follows: there was a reduction by 29 tons thanks to the consolidation of distribution sites, a reduction by 12 tons through an improvement in operations with the promotion of energy-saving and a review of the appropriate illuminance for the lighting in delivery centers, and a reduction by 62 tons thanks to switching to LED lighting.

*2 CO2 emission coefficients for electricity: we have adopted the coefficients based on Japan’s Act on Promotion of Global Warming Countermeasures (base emission coefficients for each electricity company based on actual performance for 2019 and 2020).

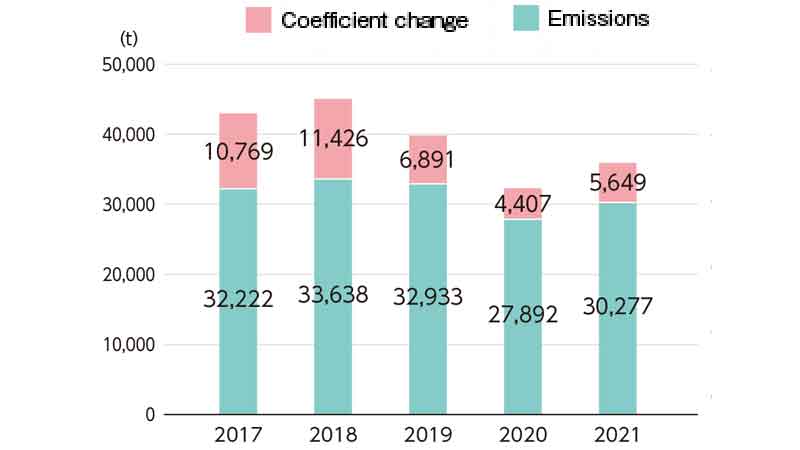

Total CO2 Emissions by KOKUYO Group

Total emissions for all 31 organizations*1 in the corporate group (which includes Iwami Paper Industry since 2018) amounted to 35,926 tons,*2 an increase of 3,627 tons from the 2020 level. The breakdown was as follows: there was an increase by approximately 1,200 tons due to a change in the emission coefficients of power companies and an increase by approximately 2,400 tons caused by a swing back from a reduction in operations due to the COVID-19 pandemic in 2020.

*1 Databank Snapshots

*2 As to CO2 emission coefficients for

electricity in Japan, we adopt the coefficients based on the Act on Promotion

of Global Warming Countermeasures (base emission coefficients for each

electricity company based on actual performance for 2019 and 2020). As to

CO2 emission coefficients for overseas electricity, we adopt

Emissions Factors 2021 by the International Energy Agency.

The difference

due to change in coefficients is the difference with the emissions calculated

based on the average of all electricity sources for 2000 (0.378

kg-CO2/kWh).

Trend of CO2 Emissions for Entire KOKUYO Group

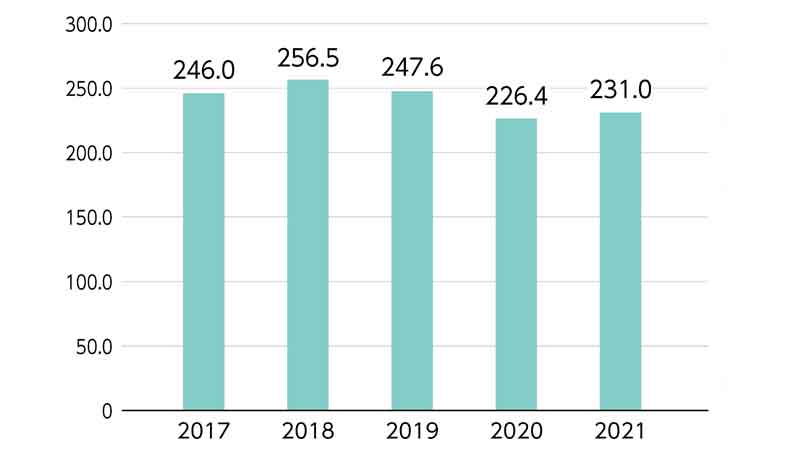

Energy consumption (energy intensity per sales unit)

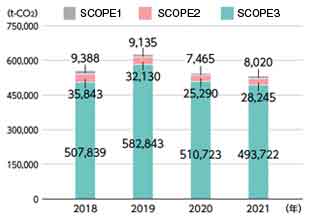

Improving the Accuracy of Scope 3 Data

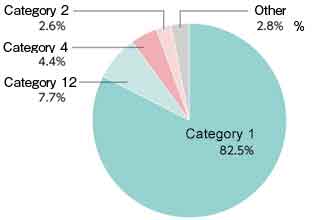

There is growing interest in carbon reporting. Businesses around the world are increasingly expected to disclose information on their scope 3 emissions. Scope 3 emissions are indirect emissions throughout the value chain, including in production, shipment, consumption, and disposal. The KOKUYO Group is also working on this issue in response to that. Greenhouse gas emissions over our supply chain in 2021 were 529,988 tons. Scope 3 emissions account for approximately 93% of all that. Furthermore, emissions classified as “category 1: purchased products and services” account for 82.5% of that.

*The reliability of our environmental data was confirmed in an independent assessment conducted Bureau Veritas Japan.

Emission by Scope

Breakdown of scope 3 emissions