Initiatives and History

1905

Zentaro Kuroda opened the Kuroda Ledger Cover Shop, a shop manufacturing covers for Japanese-style account ledgers (wacho)

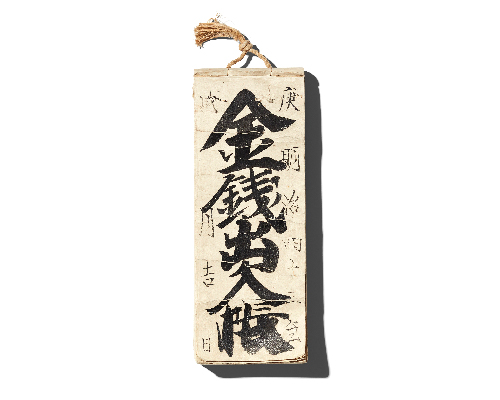

1908

Production of wacho began

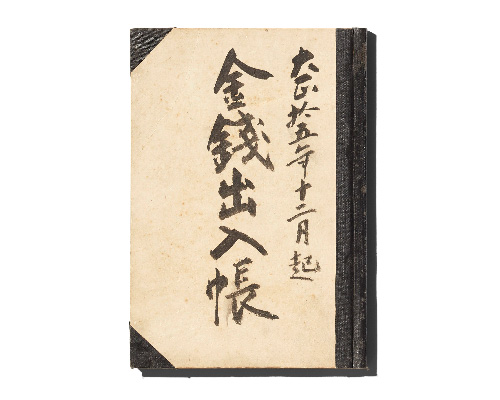

1913

Production of readymade Western-style account edgers began

1914

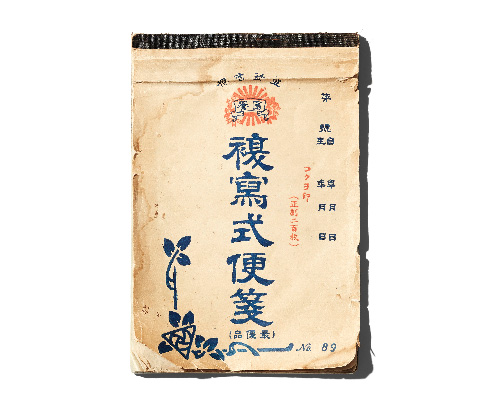

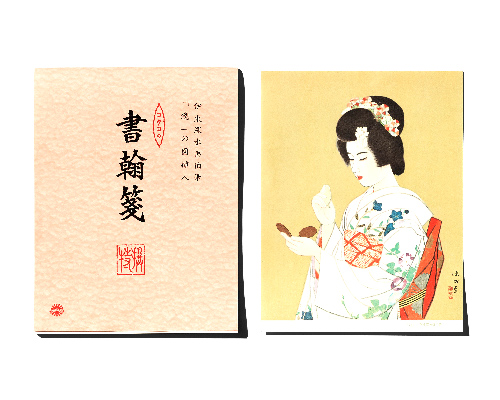

Company name changed to Kuroda Kokkodo.

Started production of accounting slips, invoices, duplicate copybooks, and letter paper

1932

Stationery pads with high-quality colored paperboard released

1956

Flat files released

1959

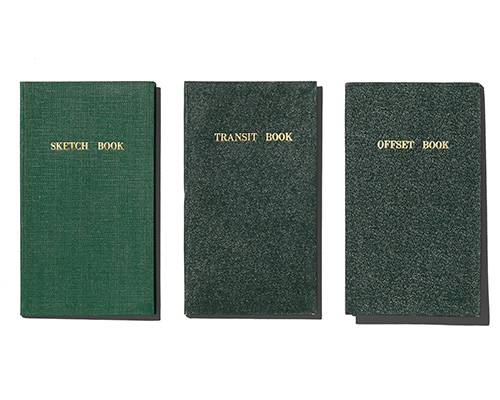

Survey filed notebooks released

1960

Entry into the office furniture business

Filing cabinets released

1961

Company name changed to KOKUYO Co., Ltd.

1964

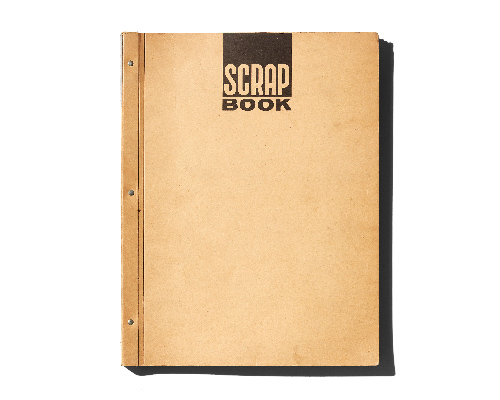

Scrapbooks released

1965

Steel desks released

1966

Office swivel chairs released

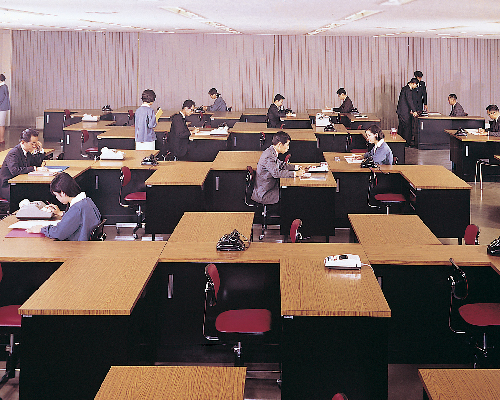

1969

Japan’s first Live Office is born

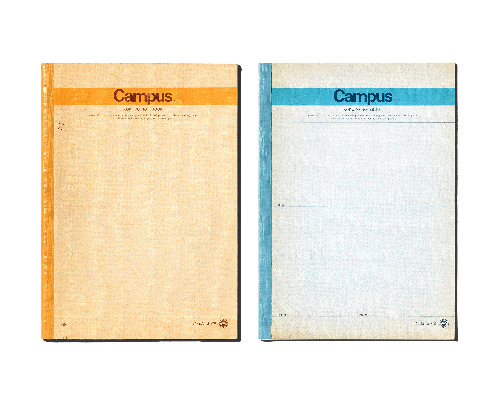

1975

Campus Notebooks released

Started manufacturing of furniture for educational facilities

1981

KuruKuruMeka (adjustable child desk) released

1983

File box FS released

1996

Established overseas group companies and started manufacturing, sales, and import and export operations of stationery and furniture

1998

Initiatives for Universal Design began

2000

Kaunet established

“PunyoPunyo Pin,” universal design-compliant thumb tacks released

2002

KOKUYO DESIGN AWARDS began

2003

KOKUYO K Heart established

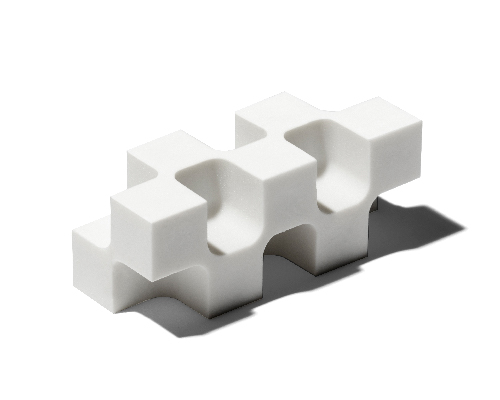

“Kadokeshi” plastic eraser released

2004

Segmented all KOKUYO Co., Ltd. businesses into separate companies and moved to holding corporation system

Dot Liner (glue tape) released

2006

KOKUYO invested in Actus Co., Ltd.

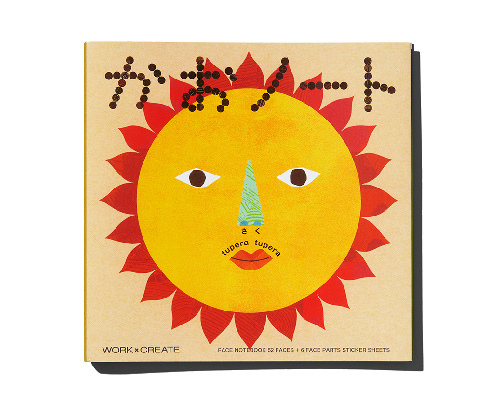

2008

Picture book series “The Face Notebook” released

2009

Harinacs (staple-free stapler) released

2011

2013

Kaucore launched

2015

Businesses reintegrated

“DAYS OFFICE” furniture brand launched

2016

In-house office bag Mobaco released

2017

Shop and café “THINK OF THINGS” opened

Office chair “ing” released

2018

Adhesive product brand “GLOO” released

2019

Launch of IoT-powered stationery: Shukudai Yaruki Pen