ENVIRONMENT

RECYCLING: ACTIONS

- Products and Services Integrating Circularity Principles

- Reducing Waste and Recycling

- Reducing and Recycling Plastic Waste

Products and Services Integrating Circularity Principles

CASE

Organization-Wide: Tsunage Loopa (an Experiential Learning Program)

Tsunage Loopa is an environmental education program that prompts participants to think about how we can look after our planet. The program brings together schoolkids in Japan, who use notebooks, KOKUYO, which makes the notebooks, and anyone engaged in recycling. In the program, schoolkids bring in used notebooks for recycling and get to see and touch the result of the recycling—new notebooks that are partly made from the old notebooks. This experience helps transform attitudes about recycling and pave the way toward a more sustainable future. As of March 2025, a total of 193 schools (roughly 52,000 pupils) have participated in this program, returning some 34,000 notebooks (roughly 4.7 tons) to us.

CASE

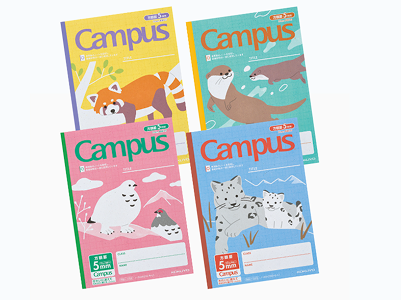

Stationery Business: Tsunage Loopa Edition of Campus Notebooks

We have released a special edition of Campus notebooks for elementary school students. The front and back covers are made from used notebooks that were returned by elementary schools participating in Tsunage Loopa. In this way, we are creating a notebook-to-notebook recycling loop that delivers notebooks back to the customer with no loss in the value of the materials. We hope that the product prompts people to think about non-wasteful ways of using many other kinds of products.

CASE

Furniture Business: Long-Life Design

We have adopted the Co.S.M.O concept, in which we use a platform for multiple furniture series, allowing for modular elements that can be reassembled and replaced as necessary. Co.S.M.O furniture has durable core structures and units with environmentally friendly designs that make the furniture as light and compact as possible, minimizing CO2 emissions during transportation. For long-selling furniture models, we extended our warranty from three to ten years in 2022. Through measures such as this, we are committing to maximizing the useful lifespan of our products and services.

CASE

Business Supply Distribution: Loopa

Kaunet Loopa is a simple, convenient, and reliable service for recycling office wastepaper. The program now collects and recycles paper packs, paper cups, confidential documents, and miscellaneous wastepaper. To facilitate the recycling of many more materials, we will incorporate a design-for-recyclability strategy (using design and manufacturing processes that enable recycling).

CASE

Interior Retail Business: Helping Maximize the Lifespan of Furniture

To reduce furniture waste, we have three services that help maximize the lifespan of furniture.

-

1.We offer a repair service that extends the furniture’s lifespan.

-

2.When users have no alternative but to discard furniture (such as when the family composition has changed or when they move house), we offer to buy back the furniture and upcycle it.

-

3.We recycle 100% of worn-out or broken furniture.

CASE

Efforts in Logistics Operations: Cleaning Service to Make Furniture as Good as New

We offer a cleaning service for fabric products such as office chairs, sofas and low-level partitions, as well as for other office furniture, including desks and storage units. Using specialized cleaning equipment (in the case of fabric products), we remove sweat stains, hand marks, dust and other dirt that has built up over years of use. We also clean all items as their (non-fabric) surfaces and structural parts require and return them to the customer as good as new.

In this way, the cleaning service helps extend the useful lifespan of valued furniture. Office furniture that is cared for in this way makes for a pleasanter working environment. At the moment this service is only available in the Tokyo area but we plan to expand it to other areas in the future.

*An item’s condition or materials, the type of dirt or how long it has gone uncleaned may make it impossible to clean items in some cases.

Reducing Waste and Recycling

The volume of waste materials generated by KOKUYO’s and our 30 consolidated subsidiaries’ business offices in 2024 was 20,314 tons (previous year: 21,153 tons), and the recycling rate was 95.7% (previous year: 94.6%). We generated 4,451 tons of waste materials on worksites (previous year:3,992 tons) with a recycling rate of 82.9% (previous year: 82.1%). We have clarified the responsibilities of the prime contractor for worksite waste disposal and made worksites more responsible for not generating waste in the first place. We started working to reduce the amount of waste generated by our worksites by, for example, reviewing our parts and materials ordering processes. As waste materials generated on worksites are not homogenous, it is often difficult to recycle, as a given batch can contain various types of waste. Nevertheless, we will continue to strive to dispose of our waste properly and to increase our recycling rate to 100%, as well as to reduce the volume of waste generated to start with.

Reducing

CASE

Reducing and Recycling at Shibayama Plant

The Shibayama Plant is working to increase its recycling rate and to boost the percentage of materials recycled for use as resources. It raised this to around 49.6% in 2024 by correctly sorting its industrial waste and by seeking help from a waste-management provider that can recover materials from glass waste, which was previously unable to recycle. The plant will continue to go further in reducing and recycling its waste.

Reusing

CASE

Resource-Efficient Deliveries (Using Foldable Crates Instead of Cardboard Boxes)

KOKUYO products are now delivered to retailers in foldable crates to minimize the use of packaging materials. Normally, the products would be delivered in cardboard boxes, which the retailers would have to dispose of themselves. The switch to foldable crates minimizes resource use. Moreover, we periodically collect the crates, which helps inculcate a commitment to a sustainable circular economy in our distribution channels.

CASE

Returning and Reusing Buffer Packaging Materials

We encourage our distribution channels to return buffer packaging materials (cushioning material that protects the contents from shocks) so that they can be reused. We have started reusing coverings that protect desk corners and door stoppers used to keep storage unit doors from opening. By recovering and reusing these materials, rather than allowing them to be thrown away after delivery, we are supporting the more efficient use of plastic resources.

Reusing, Recycling

CASE

Recycling Stretch Film Used in Warehouses

Kaunet’s warehouses and KOKUYO Logitem’s distribution centers use stretch film to prevent goods from shifting and falling. We now recover this for reuse after intermediate processing. By recovering materials that would previously have been disposed of and reusing them as materials in our products, we are reducing resource usage in product manufacture and the amount of plastic waste incinerated, thereby contributing to an environmentally friendly circular economy.

CASE

Reusing and Recycling Collected Furniture

We continue to run a collect and reuse/recycle scheme. After delivering products, we offer to take away the customer’s disused products so that they can be reused and recycled if their condition permits. In 2024, KOKUYO Logitem collected around 3,491 tons of used office furniture (desks, chairs, and so on). Around 625 tons of the collected furniture was salvaged for reuse. The remainder was dismantled and sorted for recycling.

Reducing and Recycling Plastic Waste

In 2024, the KOKUYO Group generated 3,651 tons of plastic waste, of which we recycled 88.2%. Our distribution business generated the most plastic waste and our worksites and retail and services businesses also generated a lot. Alongside working to reduce the volume of plastic waste we generate, we are also making efforts to boost the recycling rate and the quality of our recycling (transition from thermal recycling, which focuses on using waste as a fuel source, to material recycling, which focuses on turning waste into new products).

CASE

Plastic Recycling Service Loopla and Reuse within the KOKUYO Group

Kaunet, the online office products sales arm of the KOKUYO Group, offers the Loopla plastic recycling service. It recovers used clear plastic folders and reuses the plastic in office furniture parts, stationery and office products such as desk organizers.

A wide range of product lines, including popular office furniture series COODE, FABRE and picoraLivina, have used plastic recovered in this way in the manufacture of new products for 2025. We aim to bring this clear folder recovery and recycling service to the attention of more of our customers and to promote its spread.

CASE

Switching to Paper Packaging to Reduce Plastic Use

Focusing on the introduction of more eco-friendly paper packaging. We started to use plastic-free paper packaging for our SAXA brand scissors and Harinacs stapleless staplers in December 2024. This saves around 11 tons of plastic a year*.

The nature of the paper packaging allows us to print concise product information and a design on the front and information about what uses the product can be put to on the back, with an aperture enabling customers to see its texture. These innovations make it easier to communicate these brands and their features and functions to our customers.

-

*Based on the total volume of plastic used in the previous blister packs for SAXA scissors and Harinacs stapleless staplers shipped annually

CASE

The All-Paper Series

This is a series of filing products made entirely from paper. When first launched in March 2004, customers liked these products because they could be disposed of without having to separate out different types of waste. With rising awareness of the problem of plastics in our oceans, they have recently gained plastic-free eco-friendly appeal.

The All-Paper series is involved in the Ministry of the Environment’s Plastics Smart Campaign, which focuses on the global problem of ocean plastics. The campaign facilitates action on this problem through partnership with a wide range of individuals, local governments, NGOs, companies, and research agencies. We will continue to seize on the latest technologies to tackle the plastics problem.