-MATERIAL ISSUE 4- CONTRIBUTE TOWARD A CIRCULAR ECONOMY

KOKUYO Materiality Material Issue 4: Contribute Toward a Circular Economy

Basic policy

We want to use the planet’s limited resources efficiently in delivering value to customers. Accordingly, we’ve been working to recycle more of our waste and to develop ecologically sustainable products and services. As an organization that provides products that are as accessible to as many people as possible, we also aim to promote individuated zero-waste lifestyles. We’ll engage partners and customers in our efforts to help build a circular economy, one that recycles and reuses rather than wasting.

Metrics and targets for material issue

| Outcome | 2030 challenge goals | 2024 commitment goal | |

|---|---|---|---|

| KPI | |||

| Our collaboration with partners and customers leads the way toward a zero-waste society by reducing, reusing, and recycling. | Over 16% of the Japanese population participates in our programs for building a circular economy, creating positive behavioral changes in society. | At least 80% of net sales attributable to products sold by the Group (including overseas companies) that support a transition to a circular economy | 100% of new products incorporate circular-economy design principles |

| 100% of waste (office, buildout services, inventory) recycled | |||

| We conduct numerous experiments for a circular economy, encouraging more companies to commit. | 100% of suppliers endorse our circular-economy design principles | 100% of key suppliers (some 400 companies) provided feedback (evaluations, issues to address) in supplier evaluation survey | |

Accomplishments in 2023, plans for 2024

| Accomplishments in 2023 | Plans for 2024 |

|---|---|

|

|

Implementing the basic policy

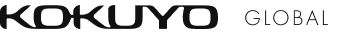

Circular business guidelines: Sutenai Circle

One of our material issues is to contribute toward a circular economy with the ideal outcome being a scenario in which our collaboration with partners contributes toward carbon neutrality throughout our supply chains. To achieve this outcome, we developed Sutenai Circle, a set of circular business guidelines, in 2023. Sutenai Circle delineates seven processes (A to G). Of these, we focus on three: Use (D), Collection (E), and Recycling (F). For these processes, we communicate with users and the venous industry (companies that turn industrial waste into reusable resources) to promote a shift to genuinely recyclable products and to develop recycling services.

Examples of business initiatives across the KOKUYO Group

Products and services integrating circularity principles

Organization-wide: Tsunage Loopa (an experiential learning program)

Tsunage Loopa is an environmental education program that prompts participants to think about how we can look after our planet. The program brings together schoolkids in Japan, who use notebooks, KOKUYO, which makes the notebooks, and anyone engaged in recycling. In the program, schoolkids bring in used notebooks for recycling and get to see and touch the result of the recycling—new notebooks that are partly made from the old notebooks. This experience helps transform attitudes about recycling and pave the way toward a more sustainable future. In 2023, 86 schools (covering some 21.5 thousand students) signed up for the program, and some 15 thousand (2 tons) notebooks were collected for recycling.

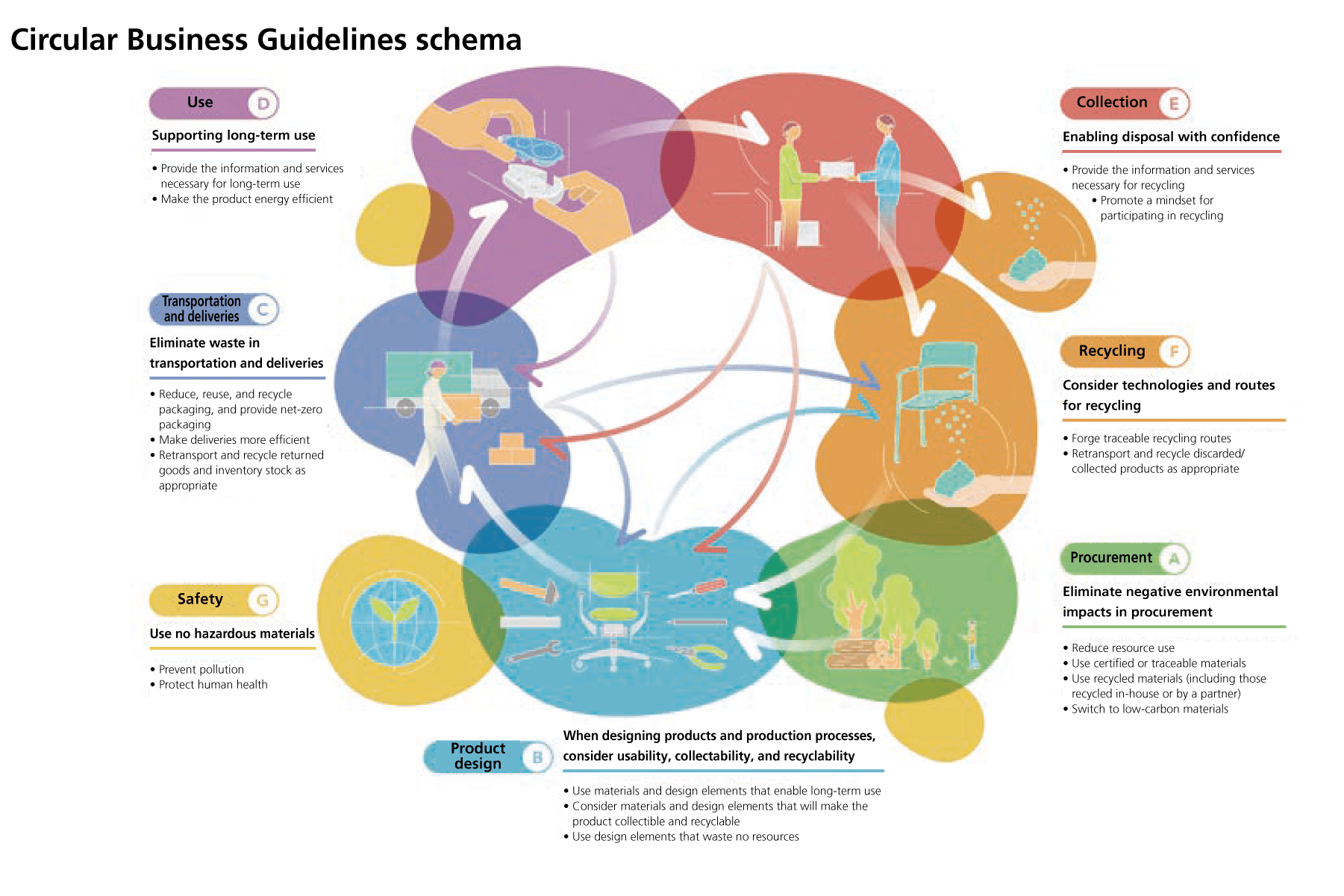

Stationery Business: Tsunage Loopa edition of Campus notebooks

We have released a special edition of Campus notebooks for elementary school students. The front and back covers are made from used notebooks that were returned by elementary schools participating in Tsunage Loopa. In this way, we are creating a notebook-to-notebook recycling loop that delivers notebooks back to the customer with no loss in the value of the materials. We hope that the product prompts people to think about non-wasteful ways of using many other kinds of products.

Furniture Business: Long-life design

We have adopted the Co.S.M.O concept, in which we use a platform for multiple furniture series, allowing for modular elements that can be reassembled and replaced as necessary. Co.S.M.O furniture has durable core structures and units with environmentally friendly designs that make the furniture as light and compact as possible, minimizing CO2 emissions during transportation. For long-selling furniture models, we extended our warranty from three to ten years in 2022. Through measures such as this, we are committing to maximizing the useful lifespan of our products and services.

Business Supply Distribution: Loopa

Kaunet Loopa is a simple, convenient, and reliable service for recycling office wastepaper. The program now collects and recycles paper packs, paper cups, confidential documents, and miscellaneous wastepaper. To facilitate the recycling of many more materials, we will incorporate a design-for-recyclability strategy (using design and manufacturing processes that enable recycling).

Interior Retail Business: Helping maximize the lifespan of furniture

To reduce furniture waste, we have three services that help maximize the lifespan of furniture.

- We offer a repair service that extends the furniture’s lifespan.

- When users have no alternative but to discard furniture (such as when the family composition has changed or when they move house), we offer to buy back the furniture and upcycle it.

- We recycle 100% of worn-out or broken furniture.

Efforts in logistics operations: Cleaning service to make furniture as good as new

We offer a cleaning service for chairs and general fabric products. Using specialized cleaning equipment, we wipe away marks made by oil-based marker pens, stains from spilt coffee, and long years of embedded dirt and grime. We also buff the frame, the front and rear of the seat and backrest, and the legs. The furniture is returned to the customer as good as new. In this way, the cleaning service helps extend the useful lifespan of the furniture. Note that the cleaning service is only available in certain areas of Japan.

Initiatives for waste

The volume of waste materials generated by the group’s 41 business offices in 2023 was 22,472 tons (previous year: 20,124 tons), and the recycling rate was 93.8% (previous year: 95.9%). We generated 4,015 tons of waste materials on worksites (previous year: 4,628 tons) with a recycling rate of 81.8% (previous year: 82.3%). The responsibilities of the prime contractor with respect to the disposition of waste materials generated in buildout processes have been clarified, and the obligations of the waste-generating company have been tightened. Efforts were made to contain waste materials in part through a review of the methods by which parts subject to processing at construction sites are ordered. As waste materials generated on worksites are not homogenous, there are many cases in which recycling is difficult due to the intermingling of various types of waste materials in a given batch. Nevertheless, we will continue to properly dispose of waste materials in conjunction with the implementation of controls on their generation and aim to achieve our target of 100% for the rate at which waste materials are recycled.

Reducing

Reducing and recycling at Shibayama plant

Shibayama plant generates about 500 tons of industrial waste every year. In 2023, the plant enhanced material recycling (recovering materials from waste without altering the chemical structure of the materials) to increase its recycling rate. The plant managed to increase its recycling rate by 3% by correctly sorting its waste. Previously, the plant found glass waste unfeasible to recycle. In 2023, however, it hired a waste management provider that could recover materials from the glass waste. Consequently, some 20% of the glass waste was subjected to material recycling in 2023. Shibayama plant will continue to go further in reducing and recycling its waste.

Reusing

Resource-efficient deliveries (using foldable crates instead of cardboard boxes)

KOKUYO products are now delivered to retailers in foldable crates to minimize the use of packaging materials. Normally, the products would be delivered in cardboard boxes and the retailers would have to dispose of the cardboard themselves. The switch to foldable crates minimizes resource use. Moreover, we periodically collect the crates, which helps inculcate a commitment to a sustainable circular economy in our distribution channels.

Returning and reusing buffer packaging materials

We encourage our distribution channels to return buffer packaging materials (cushioning material that protects the contents from shocks) so that they can be reused. We have started reusing coverings that protect desk corners and door stoppers used to keep warehouse doors from opening. By having these goods returned and recycled, instead of being disposed of after the delivery, we are supporting the effective use of plastic resources.

Reusing, recycling

Recycling stretch film used in warehouses

Kaunet’s warehouses and KOKUYO Logitem’s distribution centers use stretch film to prevent goods from falling. The stretch film is now returned and subjected to intermediate processing, after which it can be reused. By recovering materials that would previously have been disposed of and reusing them as materials in our products, we are reducing resource usage in the production of products and reducing the amount of plastic waste that gets burned, thereby contributing to an environmentally friendly circular economy.

Reusing and recycling collected furniture

We continue to run a collect and reuse/recycle scheme. After delivering products, we offer to take away the customer’s disused products so that they can be reused and recycled according to their condition. In 2023, KOKUYO Logitem collected around 2,758 tons of used office furniture (desks, chairs, and so on). Around 199 tons of the collected furniture was salvaged for reuse. The remainder was dismantled and sorted for recycling.

A desk being dismantled and sorted

Education and training

Workshop for learning about the circular economy

We can only help create a circular economy if many employees across the KOKUYO Group understand what a circular economy is and know what hinders circularity. To that end, in 2023, we ran a workshop based on the board game Waste-Zero Game. Each team had to think of ways a used product could be used further in order to avoid having to send it to landfill, earning minus 5 points. Through this game, the teams shared ideas about the value on garbage and insights they have gained in their everyday lives. In this way, the participants reevaluated the act of throwing things away.

Sustainable procurement efforts

In 2022, we surveyed suppliers about their sustainability efforts. In 2023, we conducted another such survey. Of the 533 suppliers we contacted, 482 (90.4%) responded to the survey. We then fed back the survey results to these respondents. We will conduct another survey in 2024, aiming for a 100% response rate. To fulfill our responsibility as an organization that uses copious amounts of forestry resources (paper and timber), we will start applying standards for paper and timber procurement (see contribute toward a society that coexists with nature).

| Number of suppliers | 533 |

|---|---|

| No. of respondents | 482 |

| Response rate | 90.4% |

Third-party recognition

An NPO called GENKI Net for Creating a Sustainable Society organized a dialogue to explore the potential for collaboration in paper recycling between the public, private, and academic sectors. At the event, Kaunet Loopa was honored as a model practice for recycling office wastepaper and we received a letter of gratitude from Ryoko Kizawa, the head of GENKI Net.

The letter of gratitude is presented

voice

The Circular Economy Taskforce approaches its third year

Piloting a collect and recycle scheme for office furniture

Among the materials in used furniture, the metals tend to get recycled, but the plastic and timber materials tend to get disposed of by incineration or landfilling. This is a big concern to us, as we want to lead the way toward a zero-waste society. We are therefore piloting a collect-and-recycle scheme for our furniture. When the furniture is no longer needed, the furniture is collected and its materials—the timber and plastic materials as well as the metals—are recycled. This is not something a single company can do by itself. We work with providers of collection, intermediate processing, and recycling services who share our commitment toward a circular economy. Together, in a trial-and-improvement process, we continue our efforts to build this recycling scheme.

Workplace Business Division

Manufacturing and Production Department

Strategic Coordination Unit

Mr. Nakamura

Working with customers and suppliers on alternatives for zero-waste society

To achieve the zero-waste society KOKUYO envisages, we must engage customers and suppliers in our initiatives. In Kaunet Loopla, a recycling service run by Kaunet (which delivers KOKUYO’s mail-order / e-commerce services), customers can return their used plastic folders for recycling. With the collaboration of suppliers, the plastic is reused as materials in office essentials, like pens, correction tape, and storage. We will keep focusing on what happens to our products once they are no longer needed and develop more alternatives for zero-waste society.

Kaunet

Product Development Department, Merchandising Division

Development Group 1

Ms. Shido

A notebook recycling program that gets children to think

To create a circular economy, our actions must be future-oriented as well as present-oriented. In Tsunage Loopa, our environmental education program for elementary school students, the schoolkids get to experience horizontal recycling with something they are familiar with—notebooks. This experience prompts them to take a personal interest in the transition to a circular economy. We will keep expanding Tsunage Loopa so that it reaches more kids and builds momentum toward a zero-waste society.

Global Stationery Business Division

D2C Strategy Department

Direct Marketing Unit

Mr. Morita

Related information

Efforts to recycle plastic

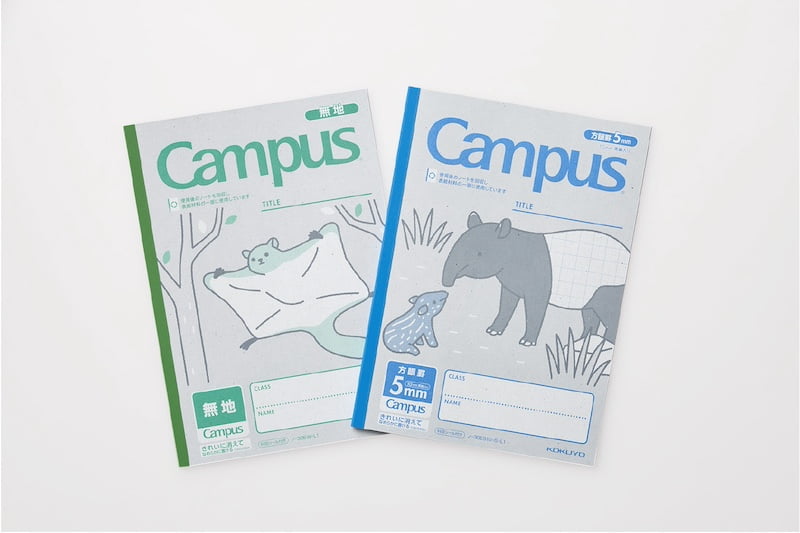

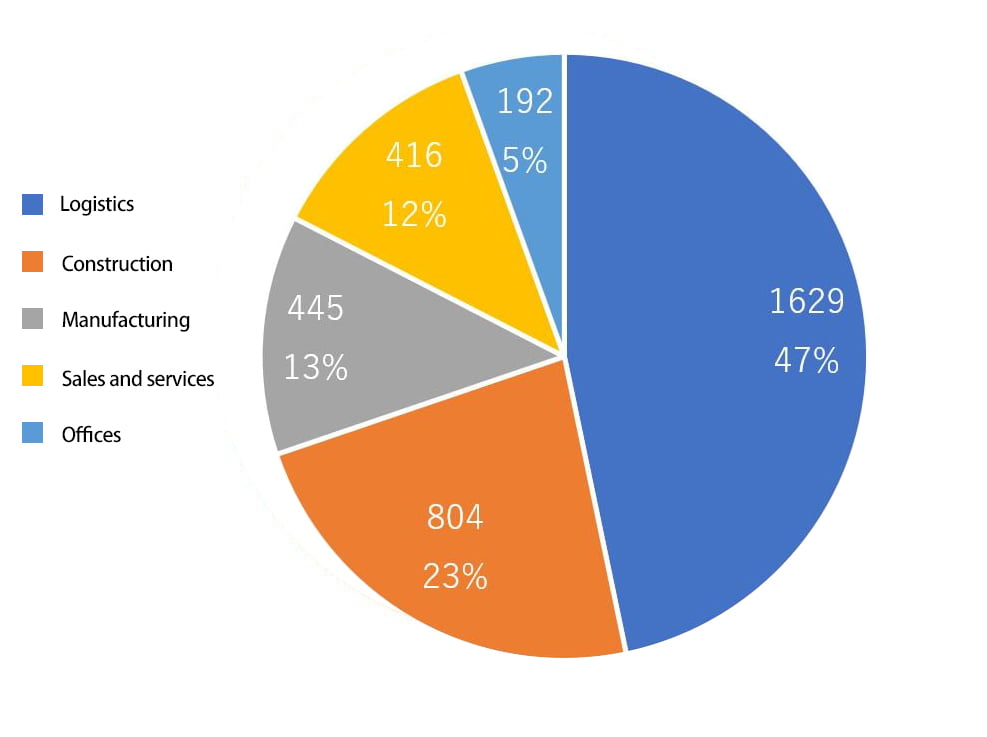

In 2023, 3,486 tons of plastic waste was generated by the KOKUYO Group, 90.3% of which was recycled.* Logistics operations accounted for the largest share of the waste generation, followed by buildout operations and manufacturing operations (operations in plants). We are working to generate less plastic waste, recycle more of the waste, and improve the quality of recycling (by switching from thermal recycling to material recycling).

This is the percentage of the total waste plastics generated by business operations in Japan. We compile data on such in accordance with the Act on Promotion of Resource Circulation for Plastics.

Inter-year comparison in plastic waste tonnage in Japan

| Year | Tons of plastic waste | Tons recycled | Tons sent to final disposal site | % recycled |

|---|---|---|---|---|

| 2019 | 4,108 | 3,819 | 289 | 93.0% |

| 2020 | 3,229 | 2,981 | 248 | 92.3% |

| 2021 | 3,769 | 3,515 | 254 | 93.2% |

| 2022 | 3,535 | 3,145 | 391 | 88.9% |

| 2023 | 3,486 | 3,149 | 337 | 90.3% |

Plastic waste tonnage by business category

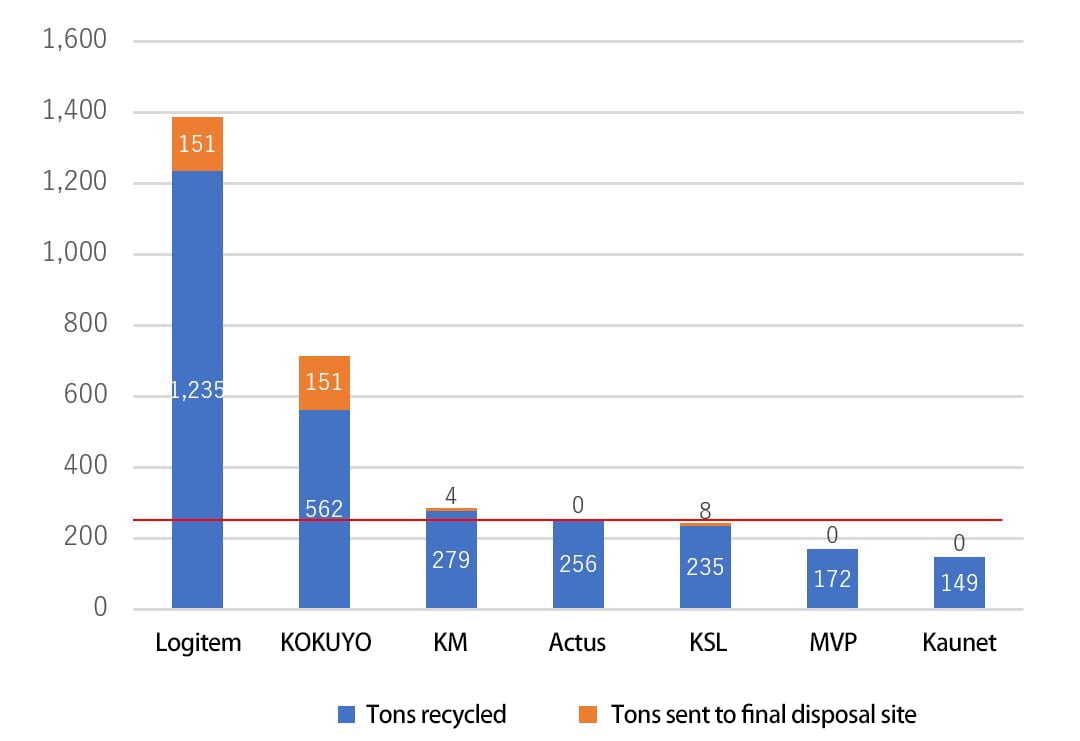

Plastic waste tonnage by group company

Under the Act on Promotion of Resource Circulation for Plastics, a company is classified as a large quantity generator if it generated at least 250 tons of plastic waste in the previous year.

The All-Paper series

This is a series of filing products made fully from paper. When it was launched in March 2004, the series received praise for the fact that one could dispose of the products without having to separate them into paper, resin, metal and other materials. With the recent global rise in the problem of ocean plastics, the series is again gaining recognition from the perspective of moving away from plastic. In 2020, we added some more products to the series. One of the new products is a folder with a window which lets you see the contents. Another is a large-capacity flat file.

The All-Paper series is involved in the Ministry of the Environment’s Plastics Smart Campaign, which focuses on the global problem of ocean plastics. The campaign facilitates action on this problem by through partnership with a wide range of individuals, local governments, NGOs, companies, and research agencies.

We are a member of the Japan Clean Ocean Material Alliance (CLOMA), and such membership helps us stay abreast of the latest technological advances in addressing the problem of ocean plastics.

Large-capacity flat file (from the All-Paper series)

Paper folder with window (from the All-Paper series)

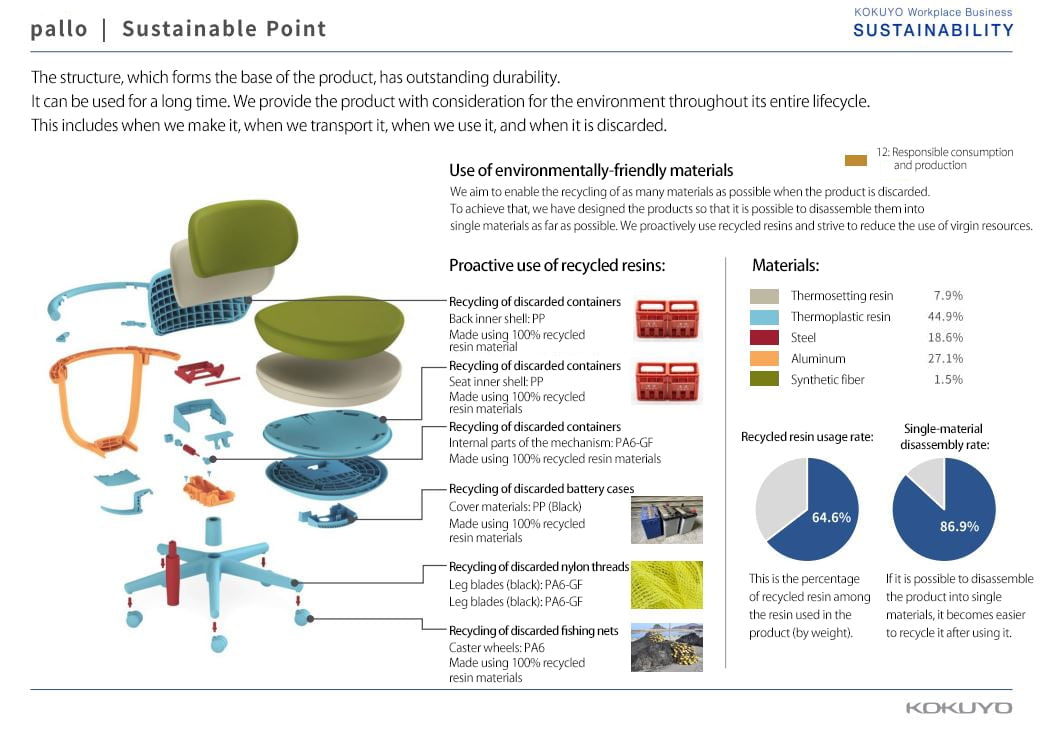

Low-plastic products

In the furniture business, we actively use recycled resins in our products. Some resins are recycled from discarded fishing gear and others from manufacturing scraps. Our website discloses details about these recycled materials. We also try our best to design products so that, once they reach the end of their life, they can be broken down into mono materials, which allows for more recycling.

Disclosing information about product materials